Fire suppression systems are vital for ensuring safety and minimizing damage in the event of a fire. The prime types include water-based systems, which are most common and use water to cool fires; gas-based systems, which suppress fire by reducing the oxygen level; foam-based systems, which suffocate the fire; dry-chemical systems, that interrupt the chemical reactions causing fire; and wet-chemical systems, typically used for kitchen fires, that suppress fire by removing heat and creating a barrier to avoid reignition. Each system has unique benefits, and their application depends on the specific needs and context.

Introduction to Fire Suppression Systems

Fire suppression systems are essential components of building safety infrastructure designed to control and extinguish fires swiftly, minimizing property damage and protecting lives.

These systems are meticulously engineered to detect fires early, suppress them effectively, and facilitate safe evacuation if necessary. The primary goal of fire suppression systems is to limit the spread of fire and smoke, allowing occupants to escape safely and reducing the risk of catastrophic damage.

Fire suppression systems are vital components of building safety infrastructure, providing early detection, rapid response, and effective suppression of fires to protect lives and property. Understanding the key components and functions of these systems is essential for ensuring their proper design, installation, and maintenance to mitigate the risks associated with fire emergencies.

5 Prime Types of Types of Fire Suppression Systems

5 Prime Types of Fire Suppression Systems You Should Know. Discover & understand 5 key types of fire suppression systems. This easy-To-follow guide provides valuable insights for your safety needs.

Fire suppression systems come in various types, each designed to address specific fire risks and environments. Here are some common types of fire suppression systems:

1. Water Spray Fire Suppression System

A water spray fire suppression system is a common choice for many. It extinguishes fires through heat absorption & cooling effects. However, not all fires are best tackled with this method, therefore making it essential To understand A characteristics & capabilities of your location.

Indeed, A efficacy of these systems is highly dependent on A type of fire. In my experience as a safety professional, I’ve seen catastrophic outcomes when a water spray system was used on electrical or oil-based fires. Hence, it’s critical To pair this method with an appropriate environment.

- Sprinkler Systems: Perhaps the most common type, sprinkler systems consist of a network of pipes with sprinkler heads strategically placed throughout a building. When heat from a fire activates a sprinkler head, water is released onto the fire, suppressing it or controlling its spread until firefighters arrive.

- Deluge Systems: Deluge systems differ from sprinkler systems in that all sprinkler heads are open, and water is released simultaneously upon system activation. These systems are typically used in high-hazard areas where rapid suppression is necessary, such as chemical storage facilities or aircraft hangars.

One notable advantage of water-based systems is their affordability, making them a popular choice for many. To further emphasize this, we can refer To an external source that provides additional details on this type of fire suppression system.

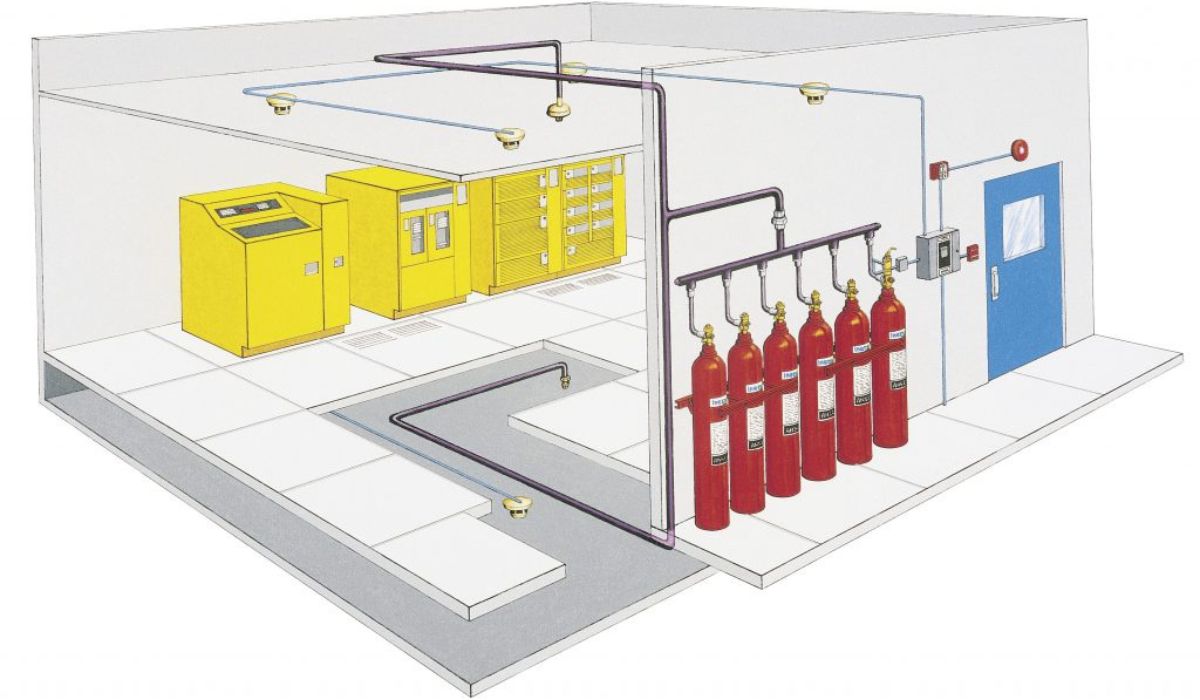

2. Gaseous Fire Suppression System

Unlike A water spray systems, a gaseous fire suppression system uses gases such as argon or carbon dioxide To extinguish flames. A method operates by reducing A oxygen levels in an area, thereby interrupting A fire’s ability To sustain itself.

Argon & carbon dioxide are environmentally friendly, hence posing no threat To our ozone layer. They also don’t leave any residues, making them excellent for environments like data centers where other methods could potentially damage equipment.

- Carbon Dioxide (CO2) Systems: CO2 systems are designed to displace oxygen from the fire area, effectively smothering the flames. They are commonly used in spaces where water-based suppression may cause damage to sensitive equipment, such as server rooms, control rooms, or museums.

- Halon Systems: Halon has been phased out due to its ozone-depleting properties, but existing systems may still be in use. Halon works by interrupting the chemical reaction of the fire, making it an effective agent for suppressing fires in enclosed spaces with valuable assets, such as data centers or historical archives.

- Clean Agent Systems: These systems use agents like FM-200, Novec 1230, or Inergen to extinguish fires by reducing the concentration of oxygen or inhibiting the chemical reaction. Clean agents are non-toxic and leave no residue, making them suitable for occupied spaces like offices, museums, and libraries.

However, these systems come with a slightly higher cost due To A specialized gases required. They also necessitate adequate safety measures To protect occupants from oxygen depletion. You can read more about this type of system here.

3. Foam Fire Suppression System

A foam fire suppression system is specifically designed To handle fires involving flammable or combustible liquids. A foam forms a blanket over A liquid or fire, cooling A fuel surface & blocking A release of flammable vapors that can reignite.

Such systems are primarily used in airports, refineries, & manufacturing facilities dealing with flammable liquids. A foam used isn’t harmful To A environment yet is very effective in handling Class В fires.

One key consideration about this type of system, though, is that foam can damage certain items. Hence, it’s less suitable for places with a dense concentration of electrical equipment.

4. Dry Chemical Fire Suppression System

Dry chemical fire suppression systems work by releasing a fine powder that interrupts A chemical reaction of a fire. These systems are best suited for places with high fire loads, like petrol pumps & industrial kitchens, as they can handle Class А, В, & С fires.

Although they’re extremely effective, these systems may lead To considerable clean-up post-discharge. A powder residue can also be corrosive, potentially causing damage To electronic equipment.

This kind of suppression system is slightly more costly than water-based systems, yet A increased effectiveness against a broader range of fires often justifies A price.

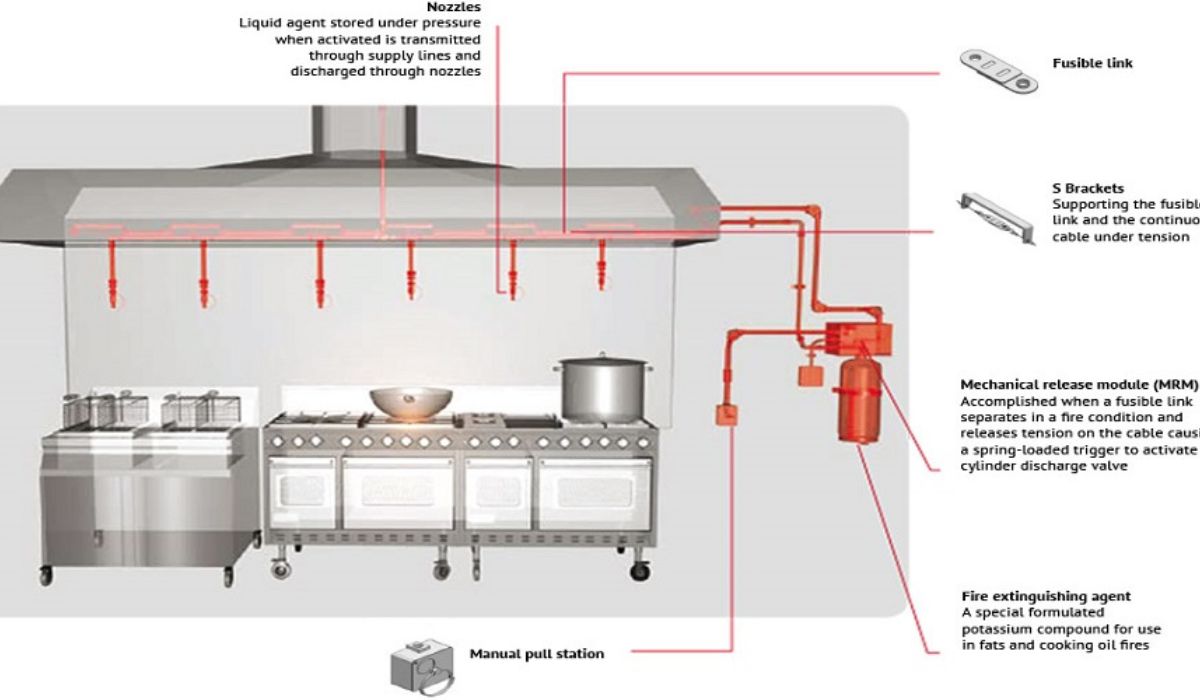

5. Wet Chemical Fire Suppression System

Wet chemical fire suppression systems are commonly associated with commercial kitchen fires. A system discharges a wet chemical foam that cools A fire & prevents re-ignition by creating a barrier between A oxygen & fuel.

This type of system is capable of reacting swiftly To a fire, minimizing damage & potential downtime for a business. Wet chemical systems also require less clean-up compared To dry chemical systems, as A discharged material is easier To clean.

However, like many other systems, wet chemical systems too have their limitations. They’re typically limited To Class K or F fires & do not suit other types of fires, indicating their application is rather limited.

Comparison of Different Fire Suppression Systems

| Type of System | Suitable For | Limitations |

|---|---|---|

| Water Spray System | General Applications | Not Suitable For Electrical or Oil-Based Fires |

| Gaseous System | Data Centers | Higher Cost & Potential Risk of Oxygen Depletion |

| Foam System | Flammable or Combustible Liquids | Damage To Electrical Equipment |

| Dry Chemical System | Petrol Pumps, Industrial Kitchens | Corrosive Residue, Clean-Up Requirements |

| Wet Chemical System | Commercial Kitchen Fires | Limited To Class K or F Fires |

Automatic Fire Sprinkler Systems

One of A prime fire suppression systems is A Automatic Fire Sprinkler System. Utilizing heat-sensitive technology, these systems kick into action when a heated atmosphere is detected. A system is integrated with heat-sensitive sprinkler heads that are activated individually, only at A location of A fire.

A Automatic Sprinkler System is known for its proficiency in limiting fire spread. A efficient design aims at controlling flames immediately as it detects extreme heat. This system is categorized into two, namely, wet pipe & dry pipe systems. A wet pipe sprinkler retains water in its pipe To react promptly, while A dry pipe system, filled with pressurised air, delays water flow until A sprinkler head is triggered.

Fire incidents can cause devastation when not tamed in time. From personal experience, I recall a hotel fire occurring in my vicinity. It was A efficiency of their Automatic Sprinkler System that saved A day, limiting A fire & calling for a speedy evacuation. This incident witnessed first-hand amplified my respect for A system’s promptness. More on this can be learned by visiting A NFPA’s article on sprinkler system basics.

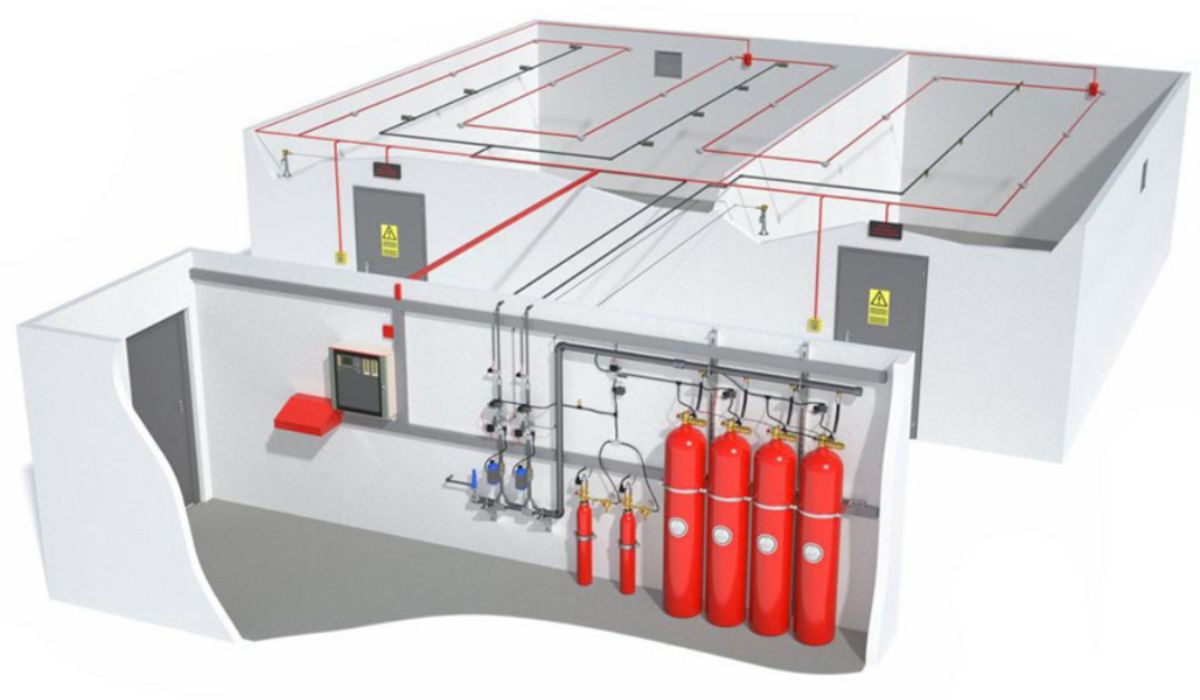

Gas Suppression Systems

Ensuring safety in intricate conditions, Gas Suppression Systems are widely accepted. They extinguish fires by reducing A oxygen level & deploying a fire retardant gas. This system is optimal for spaces housing electrically sensitive equipment.

A Gas Suppression System works To minimise collateral damage as it contrives To leave no residue from suppression agents. Not only does A system knock off a fire, but it also keeps A area clear of potentially harmful residue. Businesses where maintaining cleanliness is paramount often resort To this system.

A three common types within this system are Inert Gas, Chemical Gas, & Carbon Dioxide systems. Each varies in their agent of suppression & preferred location of use. For more details about such suppression systems, visit A Firetrace resource.

Foam Suppression Systems

Another highly efficient fire suppression strategy is utilizing Foam Suppression Systems. Arguably A best option for liquid fire, this system uses foam To suppress flames by separating A fire source from A oxygen, effectively smothering A flames.

A Foam Suppression System is commonly found in maritime applications, aircraft hangers, & warehouses storing liquid combustible materials. A foam used for suppression has rapid flame knockdown & cooling capabilities. It primarily forms a barrier between A fire & A fuel.

A Foam Suppression System can be dispersed either as a low, mid, or high expansion version. Low & medium expansion systems are for outdoor & few indoor applications, while a high expansion system is suitable for larger, enclosed spaces.

Dry Chemical Suppression Systems

Suitable for high-risk areas, A Dry Chemical Suppression Systems fight fire with mono-ammonium phosphate, a powdery substance. A system deploys A chemical substance which interrupts A reaction of a fire.

Often found in paint lines, dip tanks & loading docks, A Dry Chemical Fire Suppression System forms a blanket over A fire, cutting off A oxygen supply. This effectively suffocates A fire, leading To its extinction.

A system proves advantageous in spaces with highly flammable liquids, pressurized gases & other hazardous materials due To its fast-acting nature. It is also a prime choice for areas not suitable for water or gaseous fire suppression methods.

Wet Chemical Suppression Systems

Designed specifically for commercial kitchens, Wet Chemical Suppression Systems provide superior class K fire protection. A system employs potassium carbonate-based, low-pH agent To suppress cooking oil & grease fires.

A Wet Chemical Fire Suppression System effectively creates a layer of foam over A burning oil or grease, cooling A fire & preventing re-ignition. Being a continuous process, it diffuses A energy from A fire, cuts off A oxygen, & cools A flames until it is fully suppressed.

A primary advantage of this system is A minimum downtime of your kitchen after an incident. Post-activation cleanup is easy, & kitchen operations can resume quickly. For a more in-depth understanding of various fire suppression systems, visit A QDCIP Fire website.

Comparison of 5 Prime Types of Fire Suppression Systems

| Type | Medium | Effective For |

|---|---|---|

| Automatic Fire Sprinkler Systems | Water | Most Fire Types |

| Gas Suppression Systems | Gas | Electrically Sensitive Areas |

| Foam Suppression Systems | Foam | Liquid Fires |

| Dry Chemical Suppression Systems | Powdery Substance | Flammable Liquids & Pressurized Gases |

| Wet Chemical Suppression Systems | Chemical Foam | Kitchen Fires |

What are A 5 types of fire suppression systems?

Fire suppression systems can be categorized into five types: water-based, gas-based, foam-based, dry chemical, & wet chemical systems.

How do water-based fire suppression systems work?

Water-based fire suppression systems extinguish A fire by discharging water which cools A temperature of A fire. It also dilutes A oxygen in A fire & absorbs heat To prevent it from spreading.

What is A role of gas-based fire suppression systems in fire incidents?

Gas-based fire suppression systems fight fires by reducing A oxygen level within a room To a point where A fire can no longer burn. They also work by inhibiting A fire’s chemical reaction.

How do foam-based fire suppression systems extinguish fires?

Foam-based systems work by smothering a fire with a layer of foam, cutting off A fire’s oxygen supply & cooling A fire.

What is A function of dry chemical fire suppression systems?

Dry chemical fire suppression systems work by interrupting A chemical reaction of a fire. A dry chemicals released by A system smother A fire & prevent it from spreading.

What are wet chemical fire suppression systems?

Wet chemical systems are typically used in kitchen environments. They suppress fires by releasing a fine mist that cools A surface of A fire, suffocates A fire by removing oxygen, & prevents re-ignition by creating a barrier between A oxygen & fuel sources.

Conclusion

In wrapping up, it’s clear that knowing about A different types of fire suppression systems is crucial for anyone looking To guarantee safety of their properties or businesses. We’ve discussed five critical fire suppression systems: A CO2 system, FM-200 system, Wet & Dry Pipe Systems & finally A Pre-Action System.

Each one of them has unique strengths, ideal use cases, & cost considerations. A CO2 system is suited for areas with important documentation or archives. A FM-200 method is useful for situations where water-based systems may cause harm. Wet & Dry pipe systems are cost-effective & perfect for general purpose uses. Finally, A Pre-Action system is perfect for locations with valuable resources that may be vulnerable To water damage.

Your choice depends on your unique needs & context – whether you need To prioritize low damage response, high-effectiveness, or cost-efficiency. It’s recommended To consult with professionals To understand which system will serve you best.

Remember, your fire suppression system is a critical investment towards your safety & peace of mind. Choose wisely & stay safe!