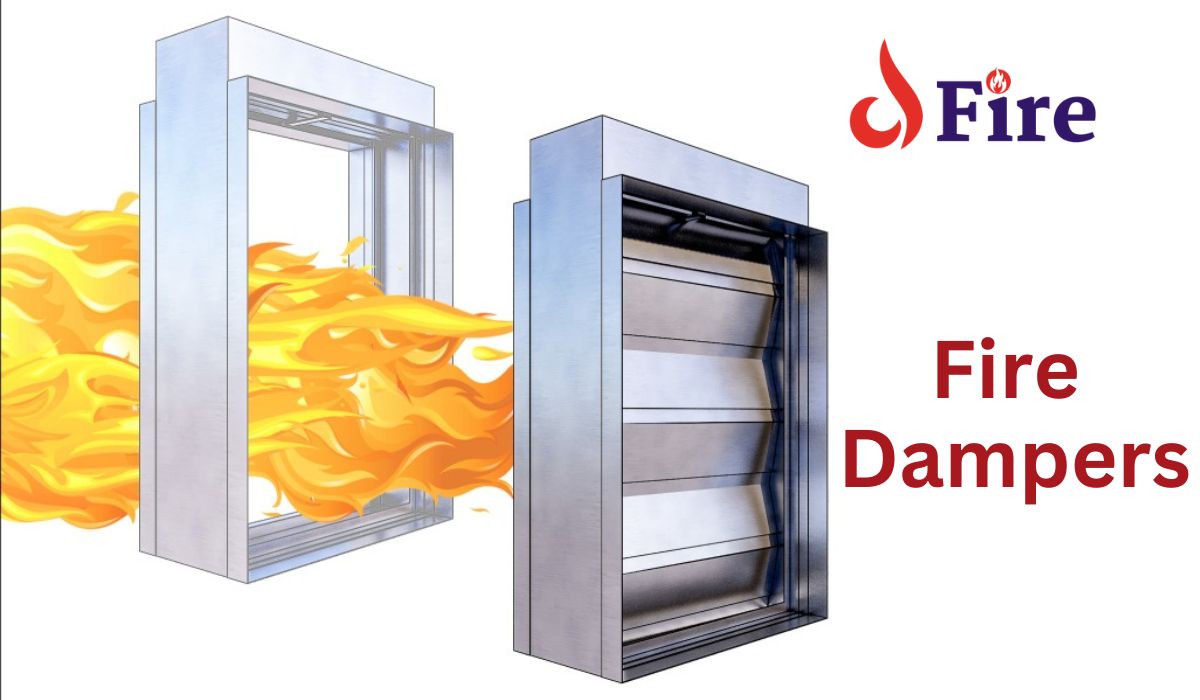

Fire dampers are safety devices installed in air ducts to prevent the spread of fire within HVAC systems. They close automatically when exposed to heat, blocking flames and smoke.

Ensuring fire safety in buildings often involves the strategic implementation of fire dampers. These critical components are a standard requirement in fire protection engineering, offering a first line of defense against the dangers of rapidly spreading fires. Their design allows them to detect high temperatures, typically caused by a nearby fire, prompting the dampers to activate and seal off the duct.

This action can slow down or even stop the progression of fire and smoke, buying essential time for evacuation and response efforts. Fire dampers come in various types, each suited to specific building requirements and fire codes. Architects, builders, and safety inspectors prioritize their proper installation and maintenance to uphold building safety standards and protect property and lives.

Fire Dampers: What They Are

Imagine a building, like a giant box of matches, vulnerable to fire. Fire dampers act like secret guardians inside the building’s ductwork. They spring into action during a fire. They block the flames and smoke from traveling through the air vents. This helps protect the building and gives people more time to escape.

Definition And Purpose

Fire dampers are safety devices found in the ducts of heating, ventilation, and air conditioning (HVAC) systems. They prevent fire and smoke from spreading inside a building. During normal conditions, they stay hidden and open, allowing air to flow through. When a fire occurs, heat activates the damper, and it closes. This cuts off the fire path, helping to contain the blaze. It’s a crucial part of a building’s fire protection system.

Types Of Fire Dampers

Fire dampers come in different shapes and sizes. They suit various needs and building codes. Below are some common types:

- Static Fire Dampers: Used in areas where airflow stops during a fire. They seal off the duct.

- Dynamic Fire Dampers: Designed for systems where fans stay on during a fire. They withstand airflow pressure.

- Ceiling Radiation Dampers: Installed in ceiling vents. They prevent fire from spreading across floors.

Each type ensures the safety of a building’s occupants and plays a role in fire containment strategies.

Importance Of Fire Dampers

Fire dampers are vital safety devices in any building’s heating, ventilation, and air conditioning (HVAC) system. They prevent fire and smoke from spreading through the ductwork. This makes them an essential part of a building’s fire protection system.

Preventing The Spread Of Fire

Fire dampers activate automatically during a fire. They close off the duct, stopping the fire from moving to other parts of the building. This action slows the fire’s progress, giving people time to escape.

- Metal curtains drop to seal off the ducts.

- Heat sensors trigger the mechanism.

- Regular maintenance ensures reliability.

Protection Of Life And Property

Fire dampers protect both people and property. They help in minimizing damage and providing a safer route for evacuation. This reduces risks for occupants and first responders.

| Benefit | Description |

|---|---|

| Life Safety | Increases the chance for safe evacuation. |

| Asset Protection | Limits property damage, saving costs. |

| Compliance | Meets legal building safety requirements. |

Working Principles Of Fire Dampers

Fire dampers play a crucial role in building safety. Understanding how they work helps us appreciate their significance in case of a fire. Their working principles rest on two fundamental processes: heat sensing and activation, and automatic shut-off mechanism. Let’s explore how each process ensures our safety.

Heat Sensing And Activation

At the core of a fire damper’s function lies its ability to detect high temperatures. This is critical for early fire detection. When the temperature within a duct system reaches a pre-determined threshold, typically around 165 degrees Fahrenheit, the fire damper springs into action.

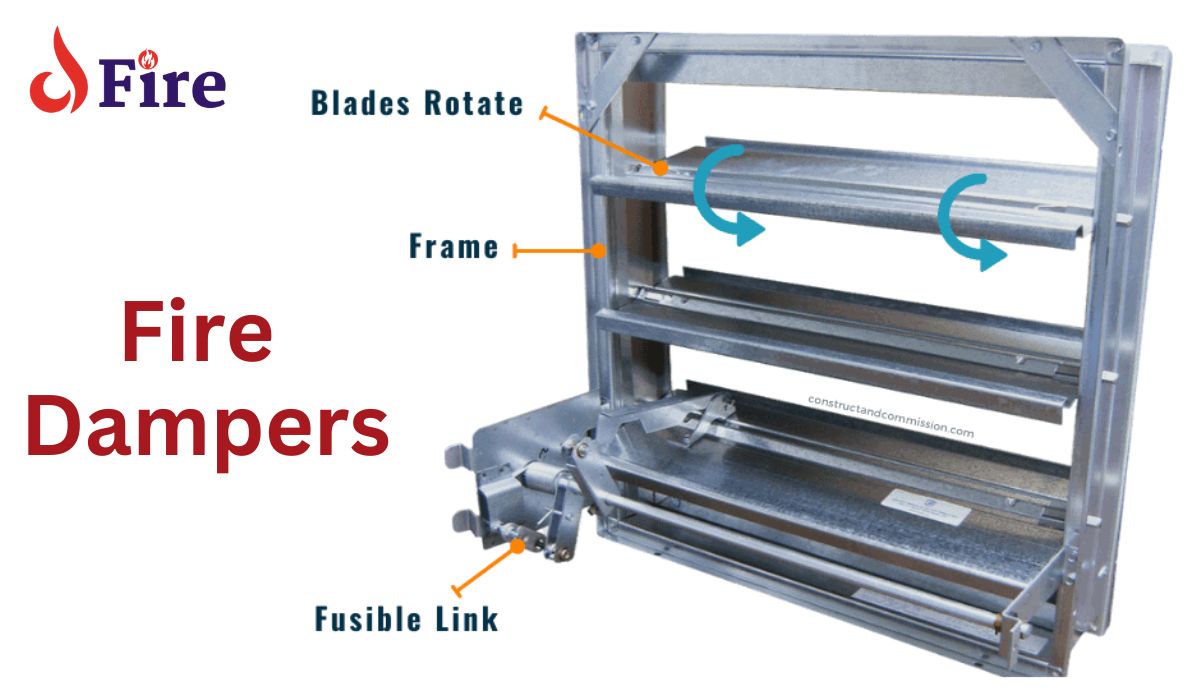

A thermal element, such as a fusible link, is designed to melt at this temperature. When it melts, it triggers the damper’s release mechanism.

- Fusible link melts at set temperatures

- Triggers release mechanism

- Engages damper closure

Automatic Shut-off Mechanism

Once activated, the fire damper must seal off the duct. This occurs through the automatic shut-off mechanism. Upon the release triggered by the thermal element, gravity or spring-loaded components force the damper blades to close off the ductwork.

This immediate action prevents fire and smoke from spreading through the ventilation system.

| Component | Action |

|---|---|

| Fusible link release | Engages shut-off |

| Spring-loaded / Gravity | Forces damper closure |

Installation Locations For Optimal Safety

When thinking about safety, knowing where to place fire dampers is key. These devices, vital for containing fires, fit in specific spots in a building’s ductwork to keep flames and smoke from spreading. Choosing the right installation locations for fire dampers can mean the difference between safety and disaster.

Hvac Systems And Fire Dampers

Fire dampers play a crucial role in HVAC systems. When there’s a fire, the dampers close automatically to block the fire’s path. This prevents it from moving through the ductwork. Install fire dampers where ductwork passes through fire-resistance rated walls and floors. This includes where air ducts intersect with:

- Vertical shafts

- Stairwell enclosures

- Elevator shafts

Fire dampers must be accessible for inspection and maintenance. This means placing them where they can be reached easily.

Critical Zones In Buildings

Critical zones in buildings need fire dampers to ensure maximum safety. Key areas include:

- Sleeping areas, where people may be unaware of a fire

- Assembly rooms, with large groups of people

- Exit pathways, to maintain clear escape routes

Fire dampers should be installed within the ductwork at these critical locations to help contain fire and smoke during an emergency.

| Location | Importance |

|---|---|

| Fire-Rated Walls | Essential barrier for flame and smoke |

| Floors | Prevent vertical fire spread |

Select fire damper locations with the intent to separate high-risk areas from the rest of the building. Proper installation and regular maintenance are critical for optimal safety.

Compliance With Fire Safety Codes

Fire dampers play a crucial role in keeping buildings safe. They prevent fire from spreading through ducts. It’s important to follow fire safety codes. This ensures dampers work right in emergencies.

Regulations And Standards

Building codes dictate fire damper requirements. They must meet specific standards. These include the National Fire Protection Association (NFPA) codes. Local laws also influence fire damper use.

- NFPA 80 Standard – Rules for installation and type.

- NFPA 90A Standard – Details how to put dampers in air systems.

Certification bodies such as Underwriters Laboratories (UL) test dampers. They ensure dampers resist fire as claimed. Compliance certificates are a must.

Regular Maintenance Requirements

Regular checks keep fire dampers ready. NFPA 80 sets these maintenance rules. Inspections should happen:

- After installation.

- One year after installation.

- Every four years, except in hospitals.

- Hospitals, every six years.

Fire dampers must stay operational. A proper maintenance schedule is essential. Include tasks such as:

| Task | Detail |

|---|---|

| Visual Inspection | Check for damage or obstructions. |

| Testing | Ensure damper closes fully. |

| Cleaning | Remove dirt that may impede function. |

Document all maintenance activities. Records prove compliance. They also help identify recurring issues.

Testing And Maintenance Protocols

Keeping fire dampers in top condition is crucial for building safety. Regular testing and upkeep ensure they function correctly during emergencies. Fire dampers act as a guard inside ventilation systems, blocking the spread of fire and smoke. Let’s explore how to maintain these vital devices.

Routine Inspection Checklists

To guarantee optimal performance, fire dampers require consistent checks. Use this checklist to ensure thorough inspections:

- Check integrity: Look for signs of damage or corrosion.

- Verify operation: Ensure dampers open and close smoothly.

- Examine components: Assess hinges, blades, and fusible links.

- Review installation: Confirm proper installation as per manufacturer guidelines.

- Documentation: Keep detailed records of every inspection.

Perform these inspections at least every 6 months for commercial buildings and annually for less intensive use.

Repair And Replacement Procedures

If inspection reveals issues, prompt action is necessary. Follow these steps for repairs and replacements:

- Identify the problem: Determine the exact issue and its extent.

- Consult manuals: Use manufacturer’s guides for specific repair protocols.

- Professional assistance: Hire qualified personnel to ensure repairs adhere to safety standards.

- Replace faulty parts: Use manufacturer-approved components.

- Test functionality: Check the repaired or replaced damper for proper operation.

Remember, if repairs are extensive, replacing the entire damper might be more cost-effective and safer.

Advancements In Fire Damper Technology

Fire dampers are critical safety devices found within heating, ventilation, and air conditioning (HVAC) systems. They play a key role in stopping the spread of fire and smoke through ducts and walls. In recent times, technology has greatly advanced in the field of fire protection, leading to innovative fire damper designs that offer superior performance and integration.

Smart Fire Dampers And Automation

The integration of smart technology into fire dampers marks a significant leap forward. Smart fire dampers work with building management systems (BMS) to provide real-time monitoring and control. This automation allows for:

- Instant alerts during a fire event.

- Remote testing for ease of maintenance.

- Seamless integration with fire alarm systems.

As a result, building safety is significantly enhanced through rapid, automated responses that these innovative systems provide.

Enhanced Materials For Improved Performance

Researchers have developed new materials to boost fire damper efficacy. These materials are crafted to endure extreme temperatures, ensuring dampers remain operational during a fire. Key improvements include:

| Material | Properties | Benefits |

|---|---|---|

| Stainless steel | High temperature resistance | Longevity and durability |

| Intumescent seals | Expand in heat | Prevent smoke leakage |

These advancements mean that fire dampers are now more robust and efficient in preventing the spread of flames and smoke, ultimately saving more lives and property.

Case Studies: Fire Dampers In Real-life Scenarios

Exploring how fire dampers operate in real scenarios can shed light on their pivotal role in fire safety. Through case studies, we learn about their success and how they can improve safety.

Success Stories In Fire Containment

Success stories offer a glimpse into the efficacy of fire dampers. In a high-rise in Dubai, fire dampers played a crucial role. An electrical fire triggered the building’s safety systems. The fire dampers activated, preventing the spread of smoke and flames through the HVAC system. This containment allowed the safe evacuation of residents and minimized property damage.

- Key Outcome: Effective containment with zero casualties.

- Takeaway: Maintenance and regular checks ensure proper damper function.

| Building Type | Fire Location | Outcome |

|---|---|---|

| High-rise residential | Electrical unit | Fire contained, no spread |

Lessons Learned From Past Fire Incidents

Studying past incidents provides valuable insights. A fire in a Chicago school sadly resulted in fatalities. Post-incident analysis showed non-functional dampers. Neglected inspection and maintenance were the main issues.

- Regular inspections are vital.

- Invest in quality fire dampers.

- Staff training on fire safety protocols is a must.

These lessons are now benchmarks for fire safety practices globally.

Frequently Asked Questions Of What Are Fire Dampers

What Is The Purpose Of Fire Dampers?

Fire dampers prevent the spread of fire through ductwork in heating, ventilation, and air conditioning (HVAC) systems. They close automatically during a fire, blocking flames and smoke.

Where Is Fire Damper Required?

Fire dampers are required in HVAC systems where air ducts penetrate fire-rated barriers, such as walls, partitions, and floors to prevent the spread of fire within the ductwork.

What Does A Fire Damper Look Like?

A fire damper is a metal device, resembling a grille or louver, situated in ductwork that automatically closes to prevent fire spread.

What Are The Three Types Of Fire Dampers?

The three types of fire dampers are static fire dampers, dynamic fire dampers, and combination fire/smoke dampers.

What Is A Fire Damper?

A fire damper is a device installed in ducts and air transfer openings that automatically closes upon the detection of heat to prevent the spread of fire within the ventilation system.

How Do Fire Dampers Work?

Fire dampers work by utilizing a thermal element that releases, allowing the damper to close, when the surrounding temperature rises above a certain threshold, typically indicating a fire.

Conclusion

Understanding fire dampers is crucial for building safety. These devices play a vital role in preventing fire and smoke spread through ductwork. It’s essential to regularly maintain and inspect them to ensure they function correctly during emergencies. Stay informed and prioritize safety with fire damper knowledge.

I’m Abdus Sobur, a highly skilled and professional Fire Safety Officer with a passion for safeguarding lives and property. Over the course of my career, I’ve conducted numerous successful fire safety audits, earning a reputation for excellence in ensuring public safety.

In addition to my role as a Fire Safety Officer, I’m also dedicated to raising awareness about the importance of fire safety. Through my blog, I share insights into the functions of different fire safety equipment, aiming to empower individuals with the knowledge they need to protect themselves and their communities.

I’m driven by a deep commitment to promoting fire safety awareness and preventing fire-related incidents.