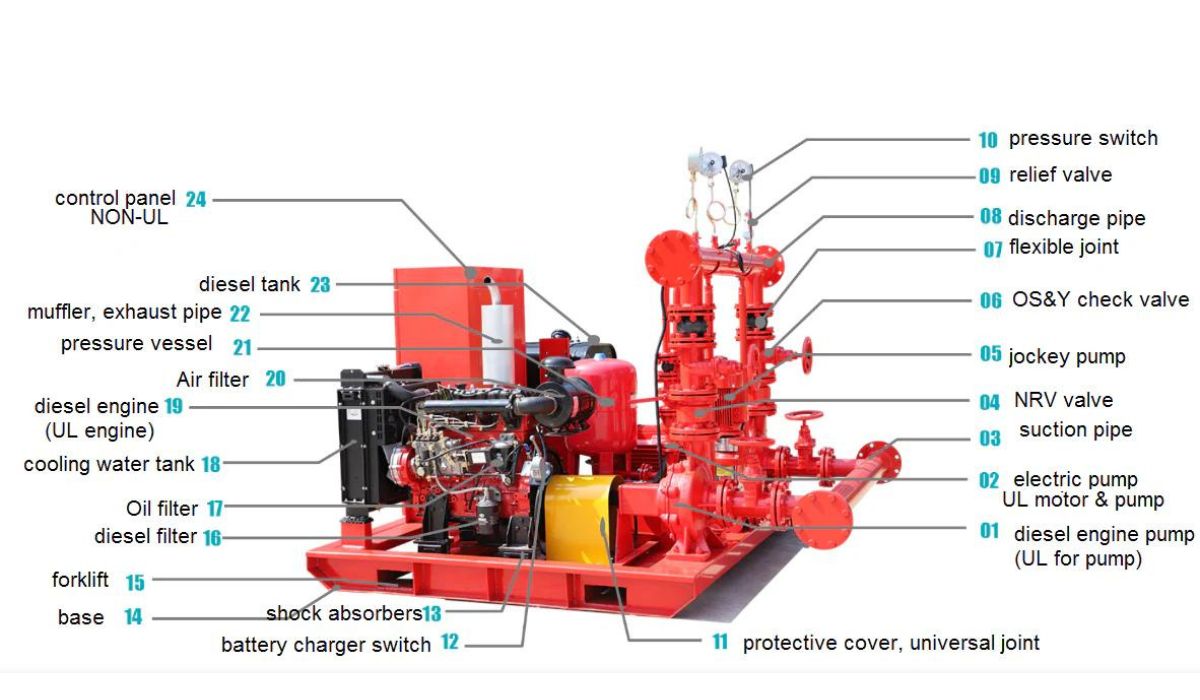

A fire pump consists of several key parts, including the pump, driver, and controller. Each component works together to deliver water at high pressure.

Fire pumps are essential for firefighting systems in buildings and industrial facilities. They ensure a reliable water supply during emergencies. The main parts include the pump, which moves water; the driver, which powers the pump; and the controller, which manages the operation.

These components must work seamlessly to provide optimal performance. Proper maintenance and regular inspections are crucial to ensure the fire pump’s reliability. By understanding the parts and their functions, facility managers can better prepare for and respond to fire emergencies, enhancing overall safety.

Introduction To Fire Pumps

Fire pumps are crucial components in firefighting systems. They ensure water is delivered efficiently. Understanding their parts and functions is essential.

Purpose And Importance

Fire pumps play a vital role in firefighting. They provide the necessary pressure to water. This pressure is needed to extinguish fires quickly.

- Ensures water reaches high-rise buildings

- Provides consistent water flow

- Essential for sprinkler systems

Basic Functionality

Fire pumps operate by drawing water from a source. They increase the water pressure significantly. This high-pressure water is then directed to fire hoses or sprinklers.

- Water is drawn from a reservoir

- Pump increases the pressure

- High-pressure water flows to firefighting equipment

| Component | Function |

|---|---|

| Pump | Increases water pressure |

| Driver | Powers the pump |

| Controller | Manages pump operation |

Pump Casing

The pump casing is a crucial part of any fire pump. It holds the water and guides it through the pump. Its design and material are essential for efficient pump operation.

Material And Design

The material of the pump casing must be durable. Common materials include cast iron, stainless steel, and bronze. These materials resist wear and corrosion. The design of the casing ensures smooth water flow. It reduces turbulence and energy loss.

| Material | Benefits |

|---|---|

| Cast Iron | Cost-effective, durable |

| Stainless Steel | Resistant to corrosion, strong |

| Bronze | High strength, corrosion-resistant |

Role In Pump Operation

The pump casing plays a key role in pump operation. It holds the water before and after it is pumped. The casing directs water to the pump impeller. It also helps in maintaining pressure inside the pump. This ensures efficient water delivery during a fire emergency.

- Holds water inside the pump

- Guides water to the impeller

- Maintains pressure

- Ensures smooth flow

A well-designed pump casing increases the efficiency of the fire pump. It also extends the life of the pump. Always check the material and design when selecting a pump casing.

Impeller

The impeller is a crucial part of a fire pump. It helps in moving water efficiently. This part spins to create pressure, pushing water through the system. Understanding the impeller’s types and functions can improve pump efficiency.

Types Of Impellers

There are different types of impellers used in fire pumps. Each type has unique features.

- Open Impeller: Has blades attached to a hub, no shroud plates.

- Semi-Open Impeller: Has a partial shroud plate on one side.

- Closed Impeller: Fully enclosed with shroud plates on both sides.

Function And Efficiency

The impeller’s main function is to create pressure. This pressure moves water through the pump. The impeller’s design affects the pump’s efficiency.

| Type | Function | Efficiency |

|---|---|---|

| Open Impeller | Handles large debris | Low to medium |

| Semi-Open Impeller | Balances debris handling and efficiency | Medium |

| Closed Impeller | High pressure and clean water | High |

A well-chosen impeller boosts the fire pump’s performance. It ensures effective water delivery during emergencies.

Credit: ylpump.en.made-in-china.com

Shaft

The shaft is a crucial component of a fire pump. It transmits the rotational power from the motor to the impeller. This process helps in moving water through the pump. Understanding the shaft’s construction and maintenance is essential for optimal pump performance.

Construction

The shaft is made from durable materials like stainless steel or carbon steel. This ensures it can withstand high pressure and intense use. The shaft has several key parts:

- Shaft Sleeve: Protects the shaft from wear and tear.

- Coupling: Connects the shaft to the motor.

- Bearings: Support the shaft and reduce friction.

Each part plays a vital role in the shaft’s operation.

Maintenance Tips

Regular maintenance keeps the shaft in good condition. Follow these tips:

- Inspect: Check for wear or damage regularly.

- Lubricate: Apply the right lubricant to the bearings.

- Align: Ensure the shaft is properly aligned with the motor.

- Clean: Keep the shaft and its parts clean from debris.

- Replace: Change worn-out parts like the shaft sleeve and bearings.

Proper maintenance extends the lifespan of the shaft and ensures smooth pump operation.

Seals And Bearings

Fire pumps are essential for firefighting systems. Two critical components are seals and bearings. Seals keep fluids inside, while bearings help parts move smoothly. Let’s explore these components in detail.

Types Of Seals

Seals prevent leaks and keep the pump efficient. There are different types of seals:

- Mechanical Seals: These are common and reliable. They use a rotating part and a stationary part to seal.

- O-Ring Seals: Made of rubber, these are simple and inexpensive. They fit into grooves to create a tight seal.

- Lip Seals: These seals use a flexible lip to keep fluids in. They are often used for low-pressure applications.

Bearing Functions

Bearings reduce friction and wear. This helps the pump parts move smoothly. Here are some key functions of bearings:

- Support Rotating Parts: Bearings support the pump shaft.

- Reduce Friction: They minimize friction between moving parts.

- Extend Lifespan: Bearings make the pump last longer by reducing wear.

Bearings come in various types:

| Type | Description |

|---|---|

| Ball Bearings | These use balls to reduce friction. |

| Roller Bearings | These use cylindrical rollers to support heavy loads. |

| Thrust Bearings | These handle axial loads and help with alignment. |

Maintaining seals and bearings is crucial. Regular checks ensure the fire pump works efficiently.

.png)

Credit: www.119pump.com

Motor

The motor is the heart of a fire pump system. It ensures the pump operates efficiently during emergencies. There are two main types of motors used: electric motors and diesel engines.

Electric Motors

Electric motors are commonly used in fire pumps. They are reliable and easy to maintain. These motors use electricity to power the pump. They are often preferred for their quiet operation.

Electric motors have several benefits:

- Low maintenance

- Quiet operation

- Quick start-up

- Eco-friendly

Below is a table that highlights some key features of electric motors:

| Feature | Description |

|---|---|

| Power Source | Electricity |

| Maintenance | Low |

| Noise Level | Quiet |

| Start-up Time | Quick |

Diesel Engines

Diesel engines are another option for fire pumps. They are ideal for locations without reliable electricity. Diesel engines are known for their durability and power.

Key benefits of diesel engines include:

- High durability

- Independent power source

- Robust performance

- Long operational life

Here is a table summarizing the key features of diesel engines:

| Feature | Description |

|---|---|

| Power Source | Diesel fuel |

| Maintenance | Moderate |

| Noise Level | Loud |

| Start-up Time | Moderate |

Pump Controller

The pump controller is a crucial component of a fire pump system. It manages the operation of the pump, ensuring it starts and stops at the right times. This system includes various features designed to maintain optimal performance and safety. Let’s dive into the key aspects of a pump controller.

Control Panels

The control panel is the brain of the pump controller. It houses the switches, indicators, and meters used to operate the fire pump. The control panel ensures the pump operates correctly and efficiently. Here are some common components found in control panels:

- Start/Stop Switch: Manually starts or stops the pump.

- Pressure Gauges: Displays the system’s pressure levels.

- Alarm Indicators: Alerts for any faults or issues.

- Battery Chargers: Keeps the backup batteries charged.

Safety Features

Safety is a top priority in any fire pump system. The pump controller includes several safety features to protect the system and ensure reliable operation. These features are designed to detect and respond to any problems quickly. Key safety features include:

- Automatic Start: Activates the pump during a fire emergency.

- Low Suction Pressure Alarm: Alerts if the water supply is too low.

- Overcurrent Protection: Prevents damage from electrical overloads.

- Emergency Stop: Quickly shuts down the pump if needed.

The pump controller ensures the fire pump system operates smoothly and safely. It combines advanced control panels and essential safety features. Understanding these components helps maintain a reliable fire protection system.

Pressure Relief Valve

The Pressure Relief Valve is an essential part of a fire pump system. It ensures the safety and efficiency of the pump operation. It prevents excessive pressure buildup that could cause damage.

Function

The Pressure Relief Valve maintains safe pressure levels. It opens to release excess pressure. This prevents the pump from overloading. It also helps in maintaining a steady flow of water. This is crucial during firefighting operations.

Installation Tips

Proper installation of the Pressure Relief Valve is critical.

- Ensure the valve is compatible with your pump system.

- Install the valve on the discharge side of the pump.

- Position the valve in an accessible location for maintenance.

- Check for proper alignment to avoid leaks.

- Test the valve after installation to ensure it functions correctly.

Follow these tips for a safe and efficient fire pump system.

Credit: www.firefighter.com.my

Frequently Asked Questions

What Are The Parts Of A Fire Pump?

A fire pump includes a pump, motor, controller, jockey pump, pressure relief valve, and suction/discharge gauges. These parts ensure efficient water flow during emergencies.

What Are The Main Parts Of A Pump?

A pump’s main parts include the impeller, casing, shaft, bearings, and seals. The impeller moves fluid, while the casing directs flow. The shaft transmits power, bearings support the shaft, and seals prevent leaks.

What Are The Parts Of A Fire Engine Pump Panel?

A fire engine pump panel includes gauges, control valves, intake and discharge ports, pressure relief valves, and throttle controls.

What Are The Basics Of Fire Pumps?

Fire pumps boost water pressure in fire protection systems. They activate when the water supply can’t meet demand. Key components include the pump, driver, and controller. Fire pumps can be electric or diesel-powered. Regular maintenance ensures reliability during emergencies. Proper installation and testing are crucial for effective performance.

Conclusion

Understanding the parts of a fire pump is essential for effective fire safety. Regular maintenance ensures optimal performance. Familiarize yourself with components like the impeller, casing, and motor. This knowledge can make a significant difference in emergency situations. Stay informed and keep your fire pump in top condition to protect lives and property.

I’m Abdus Sobur, a highly skilled and professional Fire Safety Officer with a passion for safeguarding lives and property. Over the course of my career, I’ve conducted numerous successful fire safety audits, earning a reputation for excellence in ensuring public safety.

In addition to my role as a Fire Safety Officer, I’m also dedicated to raising awareness about the importance of fire safety. Through my blog, I share insights into the functions of different fire safety equipment, aiming to empower individuals with the knowledge they need to protect themselves and their communities.

I’m driven by a deep commitment to promoting fire safety awareness and preventing fire-related incidents.