Fire protection pipe is a critical component in fire suppression systems, designed to carry water or other firefighting agents. It ensures effective delivery for quenching fires and is built to withstand high pressure and temperatures.

Fire safety within buildings hinges on robust fire protection piping systems. These pipes form the backbone of sprinkler and standpipe systems, delivering extinguishing agents where needed most. Architects and engineers select materials like steel, copper, or CPVC for their durability, pressure tolerance, and compliance with fire safety standards.

It’s essential for contractors and building owners to adhere to regional codes and use certified pipes that meet industry specifications. Regular inspection and maintenance are vital to ensure that in the event of a fire, the system operates seamlessly, safeguarding lives and property. Effective fire protection piping is synonymous with peace of mind in commercial, residential, and industrial settings.

The Importance Of Fire Protection Pipe Systems

Effective fire protection systems are crucial in any building. Fire Protection Pipe Systems play a key role in these setups. They ensure water is available during a fire. This can save lives and property. Let’s dive into why these systems matter so much.

Saving Lives And Property

Fire Protection Pipe Systems transport water to the heart of the fire. This is the first line of defense against spreading flames. A well-maintained system can control a fire quickly. This can give people inside a building more time to escape. It can also help to limit damage to the building.

- Quick response: Systems activate immediately to suppress fire.

- Reduced spread: Contain fire in one area, preventing it from spreading.

- Lower heat: Decrease temperatures, helping both people and structures.

Compliance With Safety Regulations

The right Fire Protection Pipe System helps buildings meet safety standards. These regulations ensure systems are reliable in an emergency. Failure to comply can lead to fines and increased risk.

| Regulation Aspect | Benefit |

|---|---|

| Installation Standards | Guarantee system functions correctly. |

| Maintenance Requirements | Ensure systems are always ready for use. |

| Regular Inspections | Identify and fix issues promptly. |

Types Of Fire Protection Piping

Understanding the different types of fire protection piping is critical for any fire safety system. Each type provides unique methods to control and extinguish fires, offering safety and protection tailored to various scenarios. Explore the different systems designed to shield both people and properties from the dangers of fire.

Wet Pipe Systems

Wet pipe systems are the most common type of fire protection piping. They consistently contain water within the pipes, ensuring a quick response when a fire sprinkler head activates. Here are key features:

- Always pressurized with water

- Immediate water discharge when needed

- Ideal for buildings with a low freezing risk

Dry Pipe Systems

In dry pipe systems, air or nitrogen fills the pipes under pressure. When a fire is detected, the pressure drops, and water flows through. This system is designed for environments prone to freezing. Important points include:

- Pipes are not filled with water

- Suitable for cold climates

- Delay in water discharge after detection

Pre-action Systems

Pre-action systems merge the features of both wet and dry systems. They require two triggers before water release: a preliminary fire detection signal and sprinkler activation.

| Advantages | Uses |

|---|---|

| Minimizes accidental discharge | Data centers, libraries |

| Dual-action release mechanism | Art galleries, museums |

Deluge Systems

Deluge systems are designed for high-hazard areas where rapid fire spread is a concern. This system deluges the area with water through open nozzles or sprinklers upon fire detection. Characteristics to note:

- Immediate water release over wide areas

- Used in high-risk environments

- Activation through a dedicated fire alarm

Material Choices For Fire Protection Pipes

Choosing the right material for fire protection pipes is crucial. Fire protection systems depend on durable, resistant pipes to function in emergencies. Pipes must withstand high temperatures and corrosion. They should install easily, too. This guide explores top materials for fire protection pipes, with benefits and applications.

Steel Pipes: Reliability In High Temperatures

Steel pipes offer unmatched reliability amid fire hazards. Their high-temperature tolerance makes them a favorite for fire protection systems:

- Durable in extreme conditions, handling intense heat without losing integrity.

- Suitable for both wet and dry fire protection systems.

- Available in multiple sizes and thicknesses, matching various building codes.

Cpvc Pipes: Corrosion Resistance

Chlorinated Polyvinyl Chloride, or CPVC pipes, excel in resisting corrosion:

- Withstand many chemicals and high temperatures.

- Low maintenance needs keep long-term costs down.

- Can be used in light hazard applications, such as residential buildings.

Hdpe Pipes: Flexibility In Installation

High-Density Polyethylene (HDPE) pipes stand out for their flexibility:

- Easy to install with a variety of joining methods like butt-welding, electrofusion.

- Offer superior earthquake resistance due to their flexibility.

- Suitable for various environments, including underground systems.

Design Considerations For Optimal Performance

When setting up a fire protection system, every detail matters. Designing for performance ensures safety and efficiency. The right calculations, pipe sizing, and layout are critical. Proper design also includes the placement and type of fire sprinkler heads. This guide covers essential design factors for optimal system performance.

Hydraulic Calculations For System Efficiency

Hydraulic calculations help figure out water flow and pressure needs. These calculations ensure the fire protection system can deliver enough water, at the right speed, when a fire happens. Here’s what matters:

- Water Supply: Check available water and pressure.

- Pipe Length: Measure distance water travels.

- Elevation Changes: Account for height differences in the building.

- System Demand: Consider water needed to control a fire.

Pipe Sizing And Layout

Choosing the right pipe size is crucial. Too small, and water won’t flow right. Too big, and the system is costly. The layout needs to get water everywhere it’s needed. Here’s what to look at:

- Building Type: Different buildings need different designs.

- Area Coverage: Make sure pipes reach every space.

- Material: Choose materials that last and perform well.

Incorporating Fire Sprinkler Heads

Sprinkler heads play a big role in fire control. They’re like the system’s hands, putting water where it’s needed. There are different types for different spaces. Here’s what to choose based on:

| Type | Use Case |

|---|---|

| Pendant | Hang from ceilings in offices or homes. |

| Upright | On exposed pipes, good for warehouses. |

| Sidewall | For spaces without ceiling access, like hallways. |

| Concealed | Blend in with the decor while providing protection. |

Placement and spacing are key. Follow codes and guidelines to make sure every sprinkler head can do its job.

Installation Best Practices

Ensuring the safety of a building, fire protection pipes are a critical component. The installation of these pipes must be precise to guarantee effectiveness. Below are key best practices for fire protection pipe installation.

Professional Installation Teams

Trained professionals are essential for installing fire protection pipes. These teams come with the required skills and knowledge. They follow the blueprint accurately to ensure a seamless installation. Employing certified teams reduces risks and ensures long-lasting pipe functionality.

Adhering To Safety Standards

Adherence to local and international safety standards is non-negotiable. These standards cover material, design, and installation procedures. They exist to protect both the building’s integrity and its occupants. All stages must comply with codes like the NFPA and OSHA for optimal safety.

Testing And Quality Assurance

After installation, rigorous testing and quality assurance processes are crucial. These checks ensure the system operates as expected. Testing involves pressure checks, leak detection, and functional evaluations. Quality assurance confirms the system adheres to regulations and performs reliably in an emergency.

Maintenance And Inspection: A Lifecycle Approach

Maintenance and Inspection: A Lifecycle Approach to fire protection systems is crucial for ensuring their reliability and effectiveness. Much like a well-oiled machine, fire protection pipes require a structured schedule of care to perform optimally. Consistent monitoring, servicing, and upgrading are the bedrock of fire safety. A diligent lifecycle approach keeps these systems poised to protect both lives and property from the unexpected blaze.

Regular Inspections And Servicing

Regularly scheduled evaluations are foundational to the longevity and functionality of fire protection piping. Qualified professionals should conduct comprehensive checks at established intervals:

- Check valves for proper function

- Test fire department connections

- Examine system gauges

- Look for physical damages

Preventative maintenance can catch minor issues before they escalate into major problems. It also keeps systems compliant with safety regulations.

Identifying And Addressing Corrosion

Corrosion is a silent enemy to fire protection pipes. A corrosion management plan includes:

- Regularly inspecting for signs of rust and leaks

- Applying protective coatings

- Implementing corrosion monitoring technologies

Tackling corrosion early preserves system integrity. It ensures pipes will deliver water when emergencies arise.

Emergency Preparedness And Upgrades

Incorporate emergency response drills into regular maintenance schedules. This approach ensures everyone knows their role during an actual fire. Upgrade plans should correlate with industry advancements:

| Upgrade Type | Benefits |

|---|---|

| Smart detection systems | Faster response times |

| Eco-friendly suppressants | Better environmental impact |

System enhancements can sharpen efficacy, lower risks, and align with modern safety expectations.

Technological Advancements In Fire Protection Pipes

Fire protection systems are crucial for safety in any building. As technology evolves, so do the methods we use to safeguard our homes, offices, and public spaces against fire. One such area where technology plays a pivotal role is fire protection pipes. Recent advancements have significantly improved their efficiency, reliability, and environmental impact.

Smart Monitoring Systems

Modern fire protection solutions incorporate smart monitoring systems. These digital systems track a fire protection pipe’s health in real time. Easy to integrate with building management systems, they provide alerts for any issues, allowing prompt maintenance action. Key benefits include:

- Live status updates on system integrity

- Advanced analytics for predicting maintenance needs

- Immediate notifications in case of pipe leaks or failures

Automated Control Valve Technologies

Automated control valves have revolutionized fire protection. They respond faster than manual valves. This technology ensures:

| Feature | Benefit |

|---|---|

| Quick response | Immediate action during a fire incident |

| Self-testing capabilities | Ensures valves are always ready |

| Integration with Smart Systems | Centralized control and monitoring |

Environmentally Friendly Innovations

The fire protection industry is embracing environmental responsibility. Green innovations in fire protection pipes reduce waste and conserve water. Notable advancements include:

- Use of recycled materials in pipe manufacturing

- Water-saving technologies to minimize usage during testing and drills

- Non-toxic materials that eliminate harmful runoff

Case Studies: Success Stories And Lessons Learned

Exploring real-world scenarios highlights the importance of fire protection pipes. These case studies showcase both triumphs and valuable takeaways. They underline the necessity of robust fire suppression systems.

Instances Of Effective Fire Suppression

Real-life examples demonstrate the efficiency of well-designed fire protection pipes. These systems prevent disasters, saving both lives and property.

- An office tower in New York remained unscathed thanks to its advanced sprinkler system. The fire was contained within minutes. Regular maintenance played a pivotal role.

- A data center in California could continue operations after a fire incident. The fire protection system activated instantly, minimizing damage and downtime.

Analyzing Failures To Improve Future Systems

Studying instances where systems faltered uncovers critical insights. Lessons from these events refine fire safety measures.

- Inspections are crucial. A mall in Texas experienced extensive damage due to neglected inspections.

- Materials matter. In a Michigan school, substandard pipe material led to system failure during a crucial moment.

Every failure provides valuable data. Engineers use these insights to enhance future fire safety systems. These lessons lead to higher standards and safer environments.

Advanced Fire Protection Systems In Action

Implementing cutting-edge technology proves its worth in emergencies. Advanced systems detect fires early, control them fast, and save more resources.

| Location | System Type | Outcome |

|---|---|---|

| Hospital in Florida | Automated Sprinklers with Heat Sensors | Fire extinguished in under 4 minutes. |

| Library in Oregon | Water Mist System | Books and technology protected from fire and water damage. |

Advanced systems are a testament to innovation in fire safety. They show a commitment to constant improvement.

The Future Of Fire Protection Piping

The times are changing, and so is fire protection technology. Fire protection piping is a critical part of any building’s safety infrastructure. With new advances, we are not just preparing for the challenges of today but also for future safety requirements.

Emerging Trends In Fire Safety

Fire safety technology is advancing quickly. New fire protection piping materials are now in the market. These materials are lighter and can withstand high temperatures. Smart systems can detect and react to fires faster than ever.

- Non-corrosive materials are becoming the standard for longer-lasting solutions.

- Automated fire detection systems are interfacing with piping to provide quick response.

- There is an increase in self-regulating pipes that adjust water flow as needed.

Integration With Building Information Modeling (bim)

BIM is transforming how we plan and maintain buildings. Fire protection piping is no exception. BIM allows designers and builders to create 3D models of a building’s piping system. They can see how it interacts with other systems.

- 3D modeling ensures optimal pipe routing and reduces installation conflicts.

- Pipe systems integrate with overall building models for better planning.

- It helps quickly make changes to the design if issues are found.

The Role Of Government And Industry Standards

Rules from the government and industry groups shape fire protection piping. The aim is to protect people and property.

| Regulation | Description | Impact |

|---|---|---|

| NFPA Standards | Set safety measures for fire protection systems. | Ensure systems meet safety needs. |

| International Building Code (IBC) | Provides minimum requirements for building systems. | Shapes pipe design for safety and efficiency. |

Mandatory certifications and inspections ensure systems are up to date. Industry advancements find their way into these standards regularly, keeping buildings safer with time.

Frequently Asked Questions For Fire Protection Pipe

What Is Fire Protection Pipe?

A fire protection pipe is a specialized pipe used in sprinkler systems to extinguish fires, featuring durable materials that withstand high pressure and heat.

What Is The Best Pipe For Fire Protection?

The best pipe for fire protection is generally made of steel, known for its durability and heat resistance. Steel pipes, such as black steel and galvanized steel, are commonly used in sprinkler systems for their reliability.

What Type Of Pipe Is Used For Fire Fighting?

Steel pipes, specifically carbon steel or ductile iron, are commonly used for fire fighting due to their high durability and heat resistance.

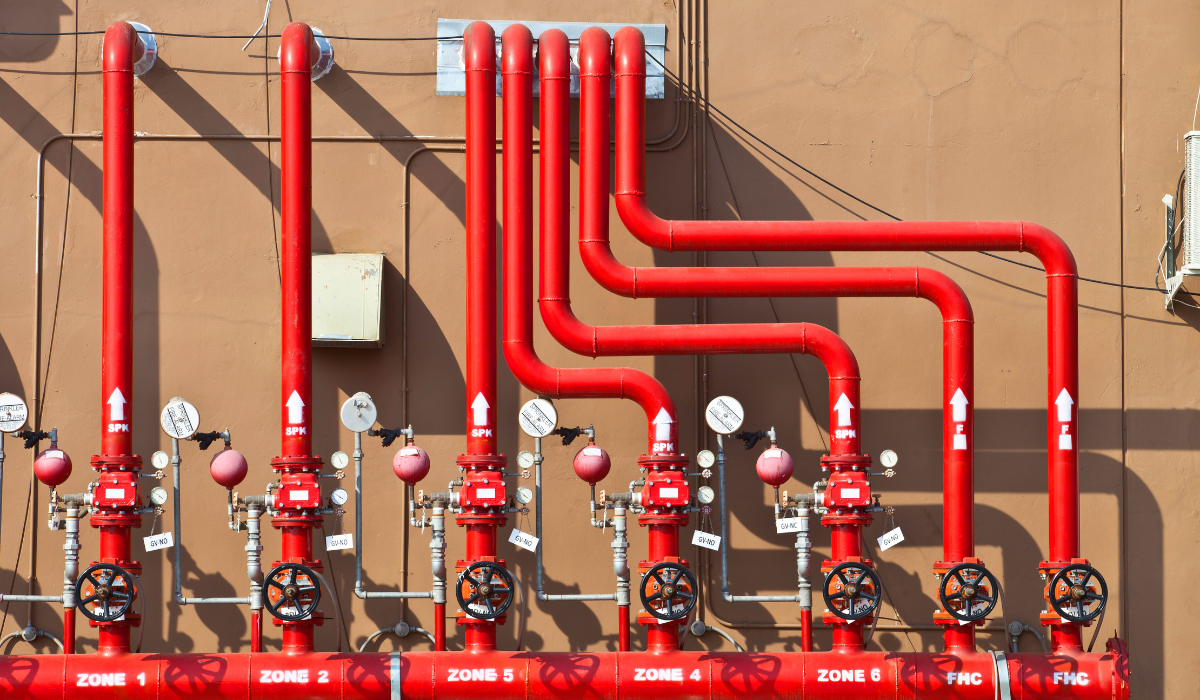

What Color Is Fire Protection Piping?

Fire protection piping typically appears in red to indicate its use in fire suppression systems. This color coding helps in quick identification during emergencies and maintenance.

Conclusion

Ensuring the integrity of your fire protection systems is paramount. By selecting the right pipes and maintenance strategies, you guard against devastating fires. Remember, regular checks and upgrades play a crucial role. Stay informed, stay safe, and protect your premises with effective fire protection piping solutions.

I’m Abdus Sobur, a highly skilled and professional Fire Safety Officer with a passion for safeguarding lives and property. Over the course of my career, I’ve conducted numerous successful fire safety audits, earning a reputation for excellence in ensuring public safety.

In addition to my role as a Fire Safety Officer, I’m also dedicated to raising awareness about the importance of fire safety. Through my blog, I share insights into the functions of different fire safety equipment, aiming to empower individuals with the knowledge they need to protect themselves and their communities.

I’m driven by a deep commitment to promoting fire safety awareness and preventing fire-related incidents.