Industrial fire and safety are crucial aspects of workplace safety that cannot be overlooked. Fire risk is present in any industrial setting, and it can cause severe damage to both property and human life. Therefore, it is essential to have proper fire safety measures in place to prevent accidents and minimize the impact of any fire-related incidents.

Various factors, including electrical faults, chemical reactions, and human error, can cause industrial fires. These fires can spread quickly and have devastating consequences.

The loss of life, property damage, and business interruption can be catastrophic, making it imperative to have a comprehensive fire safety plan. This plan should include measures such as fire prevention, detection, and suppression, as well as emergency response procedures to ensure the safety of all personnel in the event of a fire.

Industrial fire and safety is a critical issue that requires careful attention and planning. By implementing proper fire safety measures, businesses can minimize the risk of fire-related accidents and protect their employees and assets.

It is essential to educate employees on fire safety procedures and ensure that all equipment and systems are up to code and regularly maintained.

Fundamentals of Industrial Fire and Safety

Fire Chemistry and Behavior

Industrial fires can be devastating, causing loss of life, property damage, and environmental harm. Understanding the chemistry and behavior of fire is essential for preventing and managing fires in industrial settings.

Fire is a chemical reaction when three elements are present: fuel, oxygen, and heat. These elements form the fire triangle. Removing any one of these elements can extinguish a fire. For example, using a fire extinguisher to spray water on a fire removes heat and prevents the fire from spreading.

However, some fuels, such as chemicals or gases, can create a fire tetrahedron, which includes a fourth element: a chemical reaction. In these cases, removing one of the three elements of the fire triangle may not be enough to extinguish the fire. Understanding the specific properties of the fuel and how it reacts with oxygen and heat is critical for preventing and managing fires in industrial settings.

Industrial Fire Prevention Strategies

Preventing fires in industrial settings is essential for protecting employees, facilities, and the environment. The following strategies can help prevent fires:

- Regular maintenance and inspection of equipment and machinery

- Proper storage and handling of flammable materials

- Training employees on fire safety procedures and protocols

- Installation and maintenance of fire suppression systems

- Conducting regular fire drills and emergency response training

Risk Assessment and Management

Risk assessment and management are critical components of industrial fire safety. Identifying potential fire hazards and assessing their likelihood and potential consequences can help prevent fires and minimize damage in the event of a fire.

Risk assessment should include an evaluation of the following factors:

- The type and quantity of flammable materials present

- The location and accessibility of fire suppression equipment

- The training and experience of employees in fire safety procedures

- The potential impact of a fire on nearby communities or the environment

Effective risk management involves implementing strategies to reduce the likelihood and consequences of fires, such as fire prevention strategies and developing emergency response plans. Regular review and evaluation of risk management strategies can ensure their effectiveness in preventing and managing fires in industrial settings.

Industrial Fire Protection Systems

Fire protection systems are critical to ensuring the safety of personnel and assets in industrial facilities. These systems are designed to prevent, detect, and control fires. There are three main types of fire protection systems: active fire protection, passive fire protection, and fire detection and alarm systems.

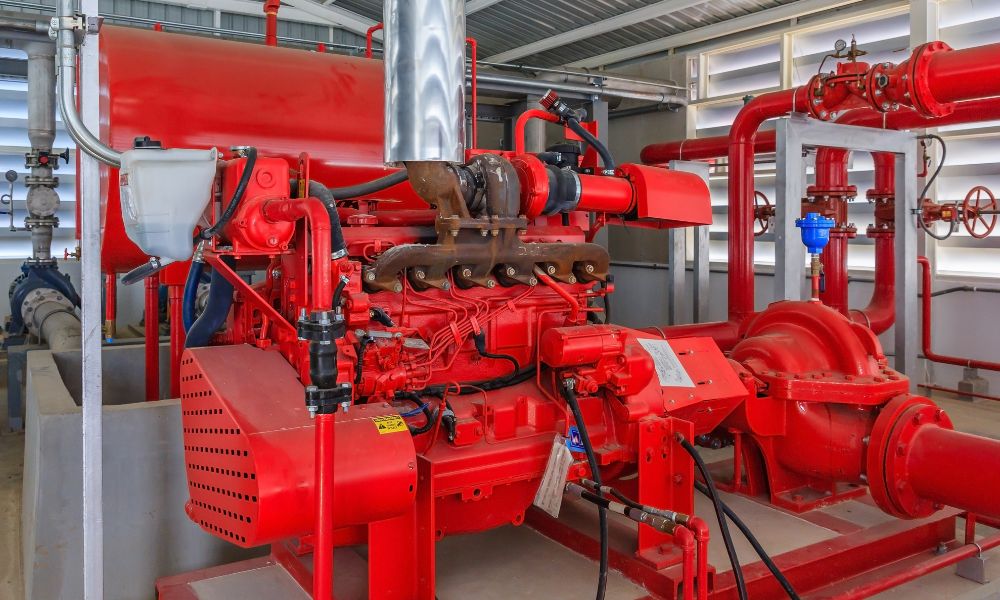

Industrial Active Fire Protection

Active fire protection systems use water, foam, or other extinguishing agents to suppress fires. These systems include fire sprinklers, fire hydrants, fire hoses, and fire extinguishers. Fire sprinklers are the most common type of active fire protection system. They are designed to detect and extinguish fires automatically by releasing water or other extinguishing agents.

Industrial Passive Fire Protection

Passive fire protection systems are designed to prevent fires from spreading. These systems include fire-resistant walls, floors, ceilings, fire doors, and fire dampers. Fire-resistant materials, which can withstand high temperatures and prevent the spread of flames and smoke, are used to construct these systems.

Fire Detection and Alarm Systems

Fire detection and alarm systems are designed to detect fires and alert personnel to evacuate the area. These systems include smoke detectors, heat detectors, flame detectors, and fire alarms. Smoke detectors are the most common type of fire detection system. They detect smoke particles in the air and trigger an alarm to alert personnel to evacuate the area.

Overall, fire protection systems are essential to ensure the safety of personnel and assets in industrial facilities. It is important to regularly inspect and maintain these systems to ensure they are in proper working order.

Emergency Response and Evacuation for Industrial Fire and Safety

Emergency Planning

Effective emergency planning is crucial for industrial fire and safety. Employers must establish and maintain an emergency action plan (EAP) that outlines procedures for responding to emergencies and evacuating employees. The EAP should include a list of emergency contacts, evacuation routes, and procedures for reporting emergencies.

Evacuation Procedures

In an emergency, employees must be able to evacuate the building quickly and safely. Employers should establish clear evacuation procedures, including designated routes and assembly points. Regular evacuation drills should be conducted to ensure that employees are familiar with the procedures and can evacuate the building quickly.

First Aid and Medical Emergencies

Employers must provide adequate first aid supplies and ensure employees are trained in basic first aid procedures. In addition, employers must have procedures in place for responding to medical emergencies, including contacting emergency medical services and providing transportation to medical facilities.

Effective emergency response and evacuation procedures are critical for industrial fire and safety. Employers must establish and maintain comprehensive emergency plans and ensure employees are trained in emergency procedures.

Personal Protective Equipment

Protective Clothing

Personal Protective Equipment (PPE) is essential for workers in industrial settings to protect them from potential hazards. Protective clothing is one of the crucial components of PPE. It includes items such as coveralls, gloves, aprons, and boots. These items protect workers from chemical spills, fire, and electrical shock.

The type of protective clothing required depends on the nature of the work and the hazards present. For example, workers must wear chemically resistant clothing when dealing with chemicals. Similarly, when working with fire, workers must wear fire-resistant clothing.

Respiratory Protection

Respiratory protection is another critical component of PPE. It is necessary when workers are exposed to harmful dust, fumes, or gases. Respiratory protection includes respirators, masks, and air-purifying devices.

Workers must select the appropriate respirator based on the work’s nature and the hazard type. For example, workers must use a respirator with a chemical cartridge when dealing with toxic gases. Similarly, workers must use a respirator with a particulate filter when working in a dusty environment.

In conclusion, Personal Protective Equipment ensures worker safety in industrial settings. Protective clothing and respiratory protection are essential components of PPE that protect workers from various hazards. Employers must ensure that workers are provided with the appropriate PPE and trained on its proper use.

Employees must be trained and educated for Industrial Fire and Safety

Fire Safety Training Programs

Training and education are essential components of industrial fire and safety. Employees must be trained on how to prevent fires, respond in case of a fire, and use fire extinguishers. Fire safety training programs should be conducted regularly to ensure employees know the latest safety procedures and protocols.

Fire safety training programs should cover topics such as the types of fires, how to prevent fires, how to use fire extinguishers, and how to evacuate in case of a fire. The training should be interactive and hands-on to ensure employees understand the procedures and protocols.

Emergency Drills and Exercises

Emergency drills and exercises are another essential aspect of industrial fire and safety. These drills and exercises help employees practice the procedures and protocols they learned during the training programs.

Emergency drills should be conducted regularly to ensure employees are prepared to respond to a fire. The drills should simulate real-life scenarios and should involve all employees. After the drills, a debriefing session should be conducted to identify improvement areas and make necessary changes to the procedures and protocols.

Current Fire Safety Regulations for Commercial and Industrial Buildings

Fire safety regulations for commercial and industrial buildings can vary depending on the location and specific regulations enforced by local authorities. However, I can provide you with a general overview of common fire safety regulations that are often applicable:

1.Building Codes:

Most jurisdictions have building codes that outline specific requirements for fire safety in commercial and industrial buildings. These codes may include provisions for building materials, construction methods, occupancy limits, and fire protection systems.

2. Fire Detection and Alarm Systems:

Commercial and industrial buildings typically require fire detection and alarm systems to alert occupants in case of a fire. These systems may include smoke detectors, heat detectors, fire alarms, and manual pull stations.

3. Fire Suppression Systems:

Depending on the size and type of the building, fire suppression systems such as sprinkler systems or fire extinguishers may be required to control or extinguish fires until the fire department arrives.

4. Emergency Lighting and Exit Signs:

Buildings must have emergency lighting to provide illumination in the event of a power failure during a fire emergency. Additionally, clearly marked exit signs must be present to guide occupants to safety.

5. Means of Egress:

Regulations typically require buildings to have multiple means of egress, such as doors, corridors, and stairways, to allow occupants to exit the building quickly in an emergency.

6. Fire-Resistant Construction:

Certain areas of commercial and industrial buildings may be required to have fire-resistant construction materials to prevent the spread of fire and provide a safe refuge for occupants.

7. Electrical Safety:

Regulations may include requirements for electrical systems to prevent electrical fires, such as proper wiring, circuit protection devices, and regular maintenance.

8. Storage and Handling of Hazardous Materials:

If the building stores or handles hazardous materials, additional regulations may apply to ensure these materials are stored safely and do not pose a fire risk.

9. Regular Inspections and Maintenance:

Building owners are often required to conduct regular inspections of fire safety systems and equipment and perform necessary maintenance to ensure they are in proper working order.

10. Training and Emergency Preparedness:

Employers may be required to provide fire safety training to employees, including evacuation procedures and the proper use of fire protection equipment.

It’s important to note that these regulations can vary significantly depending on the location and type of building, so it’s essential to consult with local authorities and fire safety experts to ensure compliance.

In conclusion, training and education are essential components of industrial fire and safety. Fire safety training programs and emergency drills and exercises should be conducted regularly to ensure that employees are aware of the latest safety procedures and protocols and are prepared to respond in case of a fire.

Frequently Asked Questions: Industrial Fire and Safety

What are the essential qualifications for a career in industrial fire and safety?

To pursue a career in industrial fire and safety, one must possess a high school diploma or equivalent. A degree in fire science or a related field is optional. Additionally, relevant work experience in fire and safety is highly valued.

What type of training is required for professionals in industrial fire and safety?

Professionals in industrial fire and safety must undergo extensive training to ensure they have the necessary skills and knowledge to handle emergencies. This training includes fire prevention, hazardous materials handling, emergency response, and rescue techniques.

What are the key equipment types used to ensure fire safety in industrial settings?

Fire safety equipment used in industrial settings includes fire alarms, fire extinguishers, sprinkler systems, smoke detectors, and fire suppression systems. These devices detect and control fires before they cause significant damage.

How can one obtain industrial fire and safety certification, and what are its benefits?

Industrial fire and safety certifications can be obtained through various organizations that offer training and certification programs. These programs cover fire prevention, hazardous materials handling, emergency response, and rescue techniques. Certification provides professionals with credibility and demonstrates to employers that they possess the necessary skills and knowledge to handle emergencies.

What are the roles and responsibilities of an Industrial Fire Department?

The primary role of an Industrial Fire Department is to prevent and respond to fires and other emergencies that occur in industrial settings. This includes conducting fire safety inspections, responding to emergencies, and educating and training employees.

What are the best practices for managing fire safety in an industrial environment?

The best practices for managing fire safety in an industrial environment include:

- Conducting regular fire safety inspections.

- Providing comprehensive training to employees.

- Maintaining fire safety equipment.

- Developing emergency response plans.

Additionally, it is essential to ensure that all employees are aware of fire safety procedures and understand their roles and responsibilities in an emergency.

I’m Abdus Sobur, a highly skilled and professional Fire Safety Officer with a passion for safeguarding lives and property. Over the course of my career, I’ve conducted numerous successful fire safety audits, earning a reputation for excellence in ensuring public safety.

In addition to my role as a Fire Safety Officer, I’m also dedicated to raising awareness about the importance of fire safety. Through my blog, I share insights into the functions of different fire safety equipment, aiming to empower individuals with the knowledge they need to protect themselves and their communities.

I’m driven by a deep commitment to promoting fire safety awareness and preventing fire-related incidents.