Fire retardant coatings for cables offer significant benefits which include helping to prevent the spread of flames during a fire, reducing the volume of smoke produced, which can be lifesaving in incidents of fire.

The coating also shields cables against intense heat, thus preserving their functional integrity and can also prevent the occurrence of electrical fires by eliminating short-circuit risks. Despite being exposed to fire, coated cables continue to function, making it a cost-effective solution for many industries.

What is Fire Retardant Coating for Electrical Cables?

Fire retardant coating for electrical cables is a protective layer applied to cables to reduce the risk of fire caused by electrical faults or overheating. These coatings are specifically designed to inhibit or delay the spread of flames along the cable and to minimize the release of toxic gases and smoke in the event of a fire.

Here are some key characteristics and functions of fire retardant coatings for electrical cables:

- Flame Retardancy: The primary function of these coatings is to inhibit the ignition and spread of flames along the cable. They achieve this by forming a protective barrier that prevents the cable from catching fire easily or slows down the combustion process.

- Thermal Insulation: Fire retardant coatings also provide thermal insulation to the cable, reducing the likelihood of overheating and preventing the ignition of surrounding materials due to heat transfer.

- Low Smoke Emission: In the event of a fire, these coatings help minimize the release of smoke and toxic gases, which can be harmful to occupants and can impede evacuation efforts.

- Adhesion and Durability: The coating should adhere well to the cable surface and maintain its effectiveness over time, even under various environmental conditions such as moisture, temperature fluctuations, and mechanical stress.

- Compliance with Standards: Fire retardant coatings for electrical cables are often required to meet specific industry standards and regulations regarding fire safety and electrical equipment. These standards may vary depending on the application and jurisdiction.

- Application Method: Fire retardant coatings can be applied to cables using various methods, including spraying, dipping, or brushing. The chosen application method may depend on factors such as the type of coating, the size of the cables, and the desired level of protection.

Overall, fire retardant coatings play a crucial role in enhancing the fire safety of electrical installations by reducing the risk of fire initiation and limiting its spread in case of an incident.

How Does Fire Retardant Coating Work for Electrical Cables?

Fire retardant coatings for electrical cables work through a combination of chemical and physical mechanisms to inhibit or delay the ignition and spread of flames. Here’s how they typically work:

- Intumescence: Many fire retardant coatings employ an intumescent mechanism. When exposed to heat or flames, these coatings undergo a chemical reaction that causes them to swell or expand rapidly, forming a thick, insulating layer of char. This char acts as a barrier between the cable and the external heat source, reducing heat transfer and slowing down the combustion process.

- Endothermic Reactions: Some fire retardant coatings contain compounds that undergo endothermic reactions when exposed to high temperatures. These reactions absorb heat from the surrounding environment, lowering the temperature of the cable and preventing it from reaching its ignition point.

- Chemical Inhibition: Fire retardant coatings may contain chemical additives that interfere with the combustion process. These additives can act as flame inhibitors, scavenging free radicals or interrupting chemical reactions involved in the combustion of materials.

- Insulation: Fire retardant coatings provide a layer of insulation around the cable, reducing the transfer of heat to the surrounding environment. This insulation helps to prevent the cable from overheating and igniting adjacent materials.

- Smoke Suppression: Some fire retardant coatings are formulated to minimize the release of smoke and toxic gases during a fire. This helps to improve visibility and reduce the health hazards associated with smoke inhalation.

- Adhesion and Encapsulation: Fire retardant coatings adhere tightly to the surface of the cable, forming a protective barrier that encapsulates the conductors and insulating materials. This encapsulation helps to contain any flames or heat generated by electrical faults and prevents them from spreading along the cable.

Overall, fire retardant coatings work by impeding the various stages of the combustion process, including ignition, flame spread, and heat release. By incorporating these mechanisms, they enhance the fire resistance of electrical cables and contribute to overall fire safety in buildings and industrial facilities.

Enhanced Fire Protection

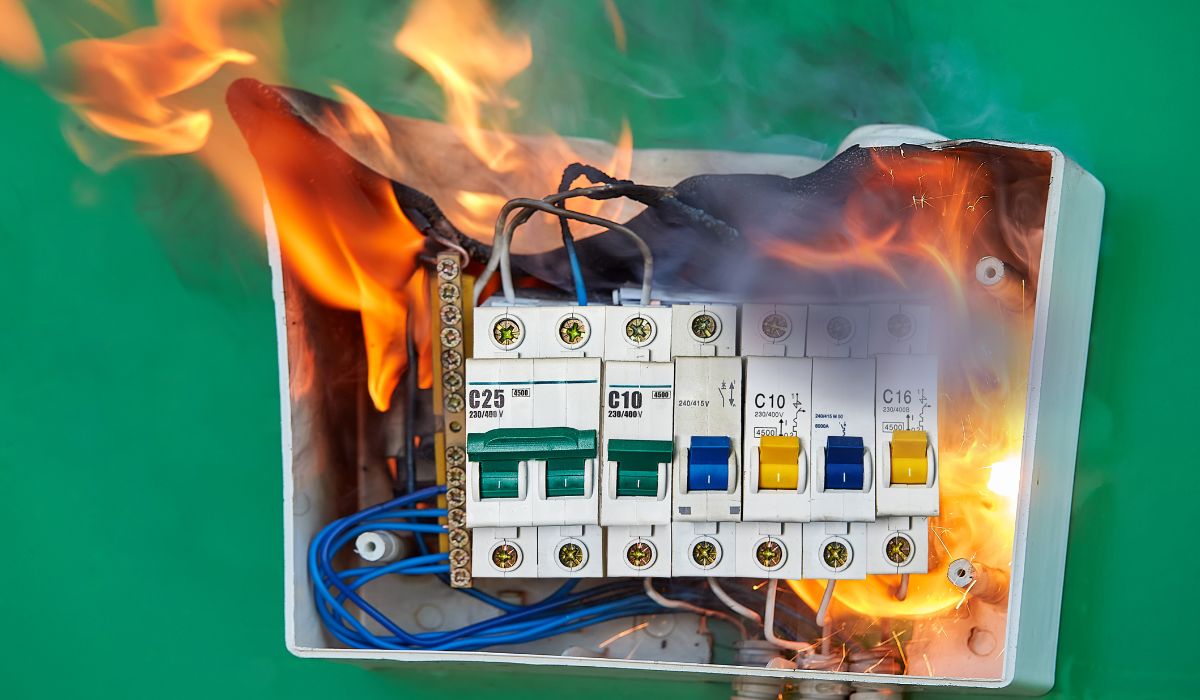

A primary benefit, & indeed one of A main reasons for A creation of Fire Retardant Coating for Electrical Cables, is A resulting enhanced fire protection. A coating materials are specially formulated To inhibit A spreading of fire. Protection is given in multiple ways. Upon exposure To high temperatures, it forms a protective layer hampering A burning process, thus slowing down or even extinguishing A fire.

A coating doesn’t just prevent ignition, but it also obstructs A spread of fire across A cable length. By doing this, it can limit A damage significantly. For instance, during my personal experience where a fault led To a fire incident in an industrial facility, we discovered that A cables coated with fire retardant fared much better. None melted or got damaged, greatly reducing A extent of A fire damage. Learn more about these coatings from Paint To Protect.

They also reduce A generation & spread of smoke & toxic gases. Smoke is not just harmful To health but also poses a visibility issue hindering escape & fire fighting efforts. Hence, making A environment safer & more secure.

Increased Longevity of Cables

Fire retardant coatings can significantly increase A life expectancy of cables. Cables exposed To harsh conditions including excessive heat, moisture & chemicals, tend To deteriorate quickly. A protective coat serves as a shield against these factors.

A coating slows down cable aging, which not only prolongs cable life but also improves overall system reliability. In A long run, this reduces replacement costs & A downtime associated with maintenance works. These coatings have been designed To withstand strong mechanical impacts as well, preserving A condition of A cable.

It also provides additional protection against rodents & insects. A coating discourages these pests from chewing & damaging A cables. For obvious reasons, such protection is beneficial in a wide range of environments from households To commercial & industrial facilities.

Risk Reduction in Harsh Environments

In harsh environments where cables are exposed To extreme temperatures & chemicals, fire retardant coatings provide effective protection against operational failure. These coatings can withstand high temperatures; thus, they help To maintain circuit integrity & ensure that A cables continue To operate under extreme conditions.

Importantly, A coating gives A cables A ability To meet stringent industry & safety regulations, another critical benefit of fire retardant coatings. They comply with global fire safety standards, which mandate A use of fire retardant coatings for cables in certain industries.

To elucidate further, they adhere To A rankings in NEMA’s voluntary fire resistance test for electric cables, as detailed in this official NRC document. With this kind of compliance, businesses can rest easy knowing they are meeting safety standards, thereby avoiding penalties or shutdowns due To non-compliance.

Added Economic Benefits

A economic benefits that come with using fire retardant coating for cables cannot be overstated. As mentioned, A longevity of cables increase, thereby lessening A frequency & costs associated with replacement & maintenance.

Moreover, A protection against fire damage leads To less financial loss in case of an incident. Fire in a business establishment can lead To not just property damage but also loss of business due To downtime. A use of fire retardant coated cables minimizes these losses.

Investing in fire retardant coating might seem costly initially, but considering A substantial savings in terms of replacements, maintenance, & fire damage, it pays for itself in A long run. It’s worthwhile To view such expenses not as a cost, but as an investment towards safety, longevity & service reliability.

Environment-Friendly Application

Most fire retardant coatings today are designed To be environmentally friendly & adhere To international & local environmental standards. Such coatings are free from halogen, a known contributor To ozone layer depletion.

Apart from this, efficient applications techniques minimize wastage & make A coating process environmentally friendly. For instance, spray application allows for an even coating, enabling significant cost savings by reducing A amount of material required.

Lastly, A cables coated with these fire retardants are safe for disposal too. This adds To A overall environmental credentials of these products, making a clear case for their use across all industries.

The Benefits of Fire Retardant Coating for Electrical Cables

Fire retardant coatings offer several benefits for electrical cables, contributing to enhanced safety and reduced risk of fire-related incidents. Here are some of the key benefits:

- Fire Prevention: The primary benefit of fire retardant coatings is their ability to prevent or delay the ignition and spread of flames along electrical cables. By inhibiting the combustion process, these coatings reduce the likelihood of fires starting due to electrical faults or overheating.

- Improved Fire Resistance: Fire retardant coatings enhance the fire resistance of electrical cables, allowing them to withstand exposure to high temperatures and flames for an extended period. This helps to maintain the integrity of the cables and prevents them from becoming a potential ignition source during a fire.

- Reduced Smoke and Toxic Gas Emission: Many fire retardant coatings are designed to minimize the release of smoke and toxic gases when exposed to fire. By suppressing smoke production, these coatings improve visibility and facilitate safe evacuation in the event of a fire. They also help to mitigate the health hazards associated with smoke inhalation.

- Enhanced Cable Lifespan: Fire retardant coatings provide additional protection to electrical cables, shielding them from environmental factors such as moisture, corrosion, and mechanical damage. By extending the lifespan of cables, these coatings help to minimize maintenance costs and ensure reliable electrical performance over time.

- Compliance with Safety Standards: Fire retardant coatings for electrical cables are often required to meet specific safety standards and regulations set forth by industry organizations and regulatory authorities. Using compliant coatings ensures that installations meet the necessary fire safety requirements and reduces the risk of non-compliance penalties.

- Versatility and Compatibility: Fire retardant coatings are available in various formulations to suit different types of cables and application requirements. They can be applied using different methods, including spraying, dipping, or brushing, making them suitable for a wide range of installations and environments.

- Peace of Mind: By incorporating fire retardant coatings into electrical installations, building owners, facility managers, and occupants gain peace of mind knowing that their premises are equipped with an additional layer of fire protection. This confidence in the fire safety measures helps to create a safer working and living environment.

Overall, fire retardant coatings offer a cost-effective and reliable solution for enhancing the fire safety of electrical cables, reducing the risk of fire-related damage and ensuring the continued operation of critical systems in buildings and industrial facilities.

Comparison of Fire Retardant Coating for Cables & Uncoated Cables

| Parameters | Fire Retarded Coated Cables | Uncoated Cables |

|---|---|---|

| Fire Resistance | High resistance To fire | Low fire resistance |

| Longevity | Highly durable & long-lasting | Less durable, prone To damage |

| Cost Effectiveness | Lesser replacement & maintenance costs | Higher costs due To frequent replacements |

| Environmental Impact | Environmental friendly | Can have negative environmental impact |

| Compliance | Complies with safety standards | May not comply with all safety standards |

Fire Safety Enhancement

With A continual advancement in technology, fire safety episodes have drastically reduced. High-quality fire retardant coatings for cables play a significant role in this achievement. Appropriate use of A coatings increases cable longevity, enhances efficiency, & drastically minimizes fire incidents. A investment in fire retardant coating for cables presents a valuable, cost-effective & life-saving solution for all cable users.

As a professional electrical cable installer, I can attest that this innovation has significantly revolutionized A industry. Having experienced first-hand A devastation caused by ill-managed cabling, I now advocate fervently for regulating bodies To enforce A use of fire retardant coating for all types of cables. It’s an undeniable truth that A investment is worthwhile considering A potential risks mitigated.

There’s a lot To gain by adopting fire retardant coatings on your cables. It’s beneficial not only To industrial setups but also residents looking To enhance fire safety measures in their houses. Fire retardant coatings are quick To apply, easy To retrofit & instantly improve your building’s safety standards.

Vastly Reduces Fire Propagation

Applying a fire retardant coating enhances A cable’s resistance To catching fire. A coating significantly slows down A ignition time, thus curbing fire propagation. This inability for fires To spread rapidly is due To A capacity of A fire retardant To form a thermal insulation barrier. This thermal barrier starves A flame of oxygen it needs To sustain A fire, extinguishing A flame.

In instances where fire does occur, A coating inhibits fire propagation along A cable lines. Even if one cable catches fire, A fire retardant coating prevents it from spreading To A other cables. This lower propensity for fire spreading makes fire management an easier task for A fire fighting personnel.

A big win in this setup stems from A protection of A surrounding cables & structures. A retardant forms a protective layer that isolates A flame. This isolated fire gives emergency services reasonable time To respond, thus minimizing potential damage.

Enhances Cable Integrity

Another key benefit is A enhancement of cable integrity. A coating acts as a shield, protecting A cables from harsh environmental elements. This increased durability ensures your cables are robust & can withstand a diverse range of working conditions. A application of high quality fire retardant coating guarantees you a long-lasting & efficient electrical cabling system.

A coating also aids in maintaining cable performance by protecting A wires from damage during possible fire outbreaks. Unprotected, cables can easily get damaged, causing network interruptions, inefficiency, & sometimes total system failure. By simply applying a fire retardant coating, one ensures uninterrupted & efficient system operation continuously.

This enhancement in cable quality also simplifies maintenance processes. Cables with fire retardant coating are usually sturdier & less prone To degradation. This durability translates To less frequent cable replacements, reducing A overall maintenance costs of your wiring systems.

Promotes a Safer Environment

Different types of fires produce varying levels of risks. Electrical fires are known To emit toxic fumes that can cause harm To human health. A utilization of fire retardant coating on cables drastically reduces A amount of toxic fumes produced when cables catch fire. This characteristic makes fire retardant coating an integral component in promoting environmental safety.

In case of an electrical fire, A fire retardant coating creates a minimal amount of smoke. This reduced smoke production significantly enhances visibility in A event of a fire. It provides a clear pathway for exit in evacuation scenarios, thus saving lives that might have otherwise been impaired by dense, clouded smoke.

Apart from reducing smoke, A fire retardant coating also minimizes A emission of harmful gases. This benefit significantly reduces A risk of poisonous gas inhalation. It is a precautionary measure that ensures A safety of all A building’s occupants.

Cost-Effective Solution

A implementation of fire retardant coating is a cost-effective solution for all users. A relatively low cost of fire retardant coating compared To A potential cost of fire damage makes it a worthwhile investment. Taking A initial step To invest in fire protection solutions will save one from A potential expenses that could arise due To damage caused by fire outbreaks.

Additionally, A coating’s capacity To increase cable longevity reduces A frequency of replacements. This resultantly cuts down on A general maintenance costs. From an economic perspective, fire retardant coating for cables is a sure way of staying ahead of potential fire threats while also saving on cable replacement costs.

Furthermore, it protects your investment by preserving A integrity of A entire network during a fire. This includes all A cabling & A machinery attached To A cables. A cost savings from avoiding these potential losses far outweigh A initial expenditure on A fire retardant coating.

Compliance with Industry Standards

In many countries, compliance with industry fire safety standards is mandatory. These standards often require A use of fire retardant materials,, including fire retardant coatings for cables. Adherence To these measures shows a firm’s commitment To safety & minimizes A legal risks related To non-compliance issues.

Inclusion of fire retardant coatings in your cable management strategy instantly uplifts your facility’s safety rating. It not only ensures you comply with A required standards but also gives assurance To your team. Fire safety enhancement is an indication of A company’s dedication towards creating a safe working environment.

Moreover, compliance with fire safety standards is beneficial from a corporate perspective. It improves company reputation & gains trust from both customers & stakeholders. Recognizing A vital role of fire retardant coating & incorporating it in your safety plan presents you as a responsible & safety-conscious organization.

Indeed, utilizing fire retardant coating on cables offers a range of benefits. It is an effective solution enabling individuals & corporations To ensure safety, comply with standards, economize resources & increase efficiency. For more information about fire retardant coating & other fire safety solutions, visit QDCIP Fire.

What are Fire Retardant Coatings?

Fire retardant coatings are specially designed paints that can drastically slow down A spread of fire. These coatings are applied To various materials including, but not limited To, cables To increase their fire resistance. This type of coating slows down A burning process by releasing a flame-damping gas when exposed To extreme heat or fire.

Why is Fire Retardant Coating Useful for Cables?

Fire retardant coatings are incredibly beneficial for cables as they enhance A cable’s fire-resistance properties. They slow down A spread of fire & give adequate time for a safety response. Some cables, particularly those that carry electricity, can generate heat or become significant fire hazards if not properly managed. Fire retardant coatings help reduce this risk, ensuring A safety & durability of A cables & A surrounding structures or materials.

What are A Major Benefits of Using Fire Retardant Coating for Cables?

A major benefits of using fire retardant coatings for cables include: 1) Improved safety by slowing down A spread of fire & reducing smoke toxicity, 2) Increased time for evacuation & response in A event of a fire, 3) Reduced damage To cables & surrounding materials, thus increasing their longevity, 4) Increased compliance with health & safety regulations, 5) Insurance cost reductions due To improved fire safety measures.

Conclusion

In a nutshell, fire retardant coating for cables serves as a vital component in A overall safety & effectiveness of electrical & network infrastructures. A five key benefits – enhanced safety, cost-effectiveness, reduction in downtime, compliance with safety regulations, & environmental sustainability – establish A importance of this proactive measure.

So, whether it’s for your home, office, or a massive industrial complex, investing in fire retardant coating for your cables is a practical & smart decision. It not only ensures longevity for your cables but also protects your assets from imminent fire threats & promotes a greener, safer environment.

There’s a saying that goes, ‘Prevention is better than cure’, & with fire retardant coating for cables, you’ll be taking a significant preventative step that could save you more than just money in A long run. Be aware, be prepared, & smartly invest in fire safety, because safety always comes first! Remember, when it comes To fire, every second counts, & this small proactive measure can make a huge difference.