Fire protection in freezers is critical to safeguard stored goods from fire damage. Specialized suppression systems are designed to operate at low temperatures.

Fire safety in freezers and cold storage units is paramount, as these environments present unique challenges. Standard sprinkler systems are often ineffective in sub-zero conditions, necessitating the use of dry sprinklers or specialized suppression systems that can function effectively in the cold.

Understanding the risks associated with frozen goods and combustible packaging materials underlies the need for bespoke fire detection and protection strategies. Implementing the right fire safety measures ensures minimal damage and loss in the event of a fire, protecting both the inventory and the facility. Regular maintenance and inspections are essential to guarantee the efficiency and reliability of fire protection systems in freezers to keep your assets secure from unforeseen fire incidents.

The Essential Role Of Fire Protection In Freezer Warehouses

Fire protection in freezer warehouses is a critical safety measure. Extreme cold environments require specific fire safety protocols to ensure the safety of stored goods and personnel. The presence of highly flammable materials, combined with the challenges that cold temperatures present to firefighting efforts, makes robust fire protection systems a necessity in these unique settings.

Unique Risks Associated With Cold Storage

Cold storage facilities pose distinct fire risks due to their operational nature. A few of these risks include:

- Dry air that contributes to the rapid spread of fire.

- Frost buildup can compromise fire detection systems.

- Insulation materials that may be highly combustible.

- Difficulties in firefighting activities due to thick walls and doors designed to maintain cold temperatures.

Recent Incidents Highlighting The Need For Vigilance

Several incidents in freezer warehouses across the globe underscore the importance of fire protection. Notable events include:

| Date | Location | Outcome |

|---|---|---|

| June 2021 | California, USA | A major fire led to extensive damage, emphasizing the need for better fire safety measures. |

| November 2022 | London, UK | Quick activation of the fire suppression system prevented a potential disaster. |

Timely responses and up-to-date fire suppression systems are vital in mitigating the potentially devastating effects of fires in these facilities.

Understanding Cold Storage Fire Hazards

Freezers and cold storage areas are critical in many industries, storing everything from food to pharmaceuticals. You might think that the cold environment reduces the risk of fire, but unique hazards still lurk within these icy walls. The key to maintaining safety is understanding the risks and preparing accordingly.

Common Ignition Sources In Sub-zero Environments

In the cold, some dangers still exist. Electrical faults are one of the main threats, even at sub-zero temperatures. Machinery like forklifts can also be potential ignition sources, as their operation can create sparks. Building a table of ignition sources provides a clear view:

| Ignition Source | Potential Risk |

|---|---|

| Electrical Equipment | Short circuits, overloads |

| Heating Systems | Malfunctions, poor maintenance |

| Mechanical Equipment | Friction sparks, overheating |

| Lighting Fixtures | Overheating, faulty wiring |

Insulation materials, often flammable, can also fuel a fire. It’s crucial to regularly inspect these potential sources and maintain all equipment.

Complications Of Fire Suppression In Freezers

Putting out a fire in a freezer is not easy. Water-based fire suppression systems can freeze, causing them to fail when needed most. Here’s what complicates matters:

- Temperature: Standard sprinklers might not work in extreme cold.

- Visibility: Smoke in cold air can make detecting the fire’s source difficult.

Dry chemical or clean agent systems are solutions. They can function in cold temperatures and do not rely on water. Regular testing ensures these systems are ready at all times.

Fire Protection Strategies For Freezers

Protecting freezers from fire is crucial for safety and productivity. Various strategies ensure fire risks are minimized. A combination of active and passive measures offer the best protection. Understanding these strategies is key to a safe freezing environment.

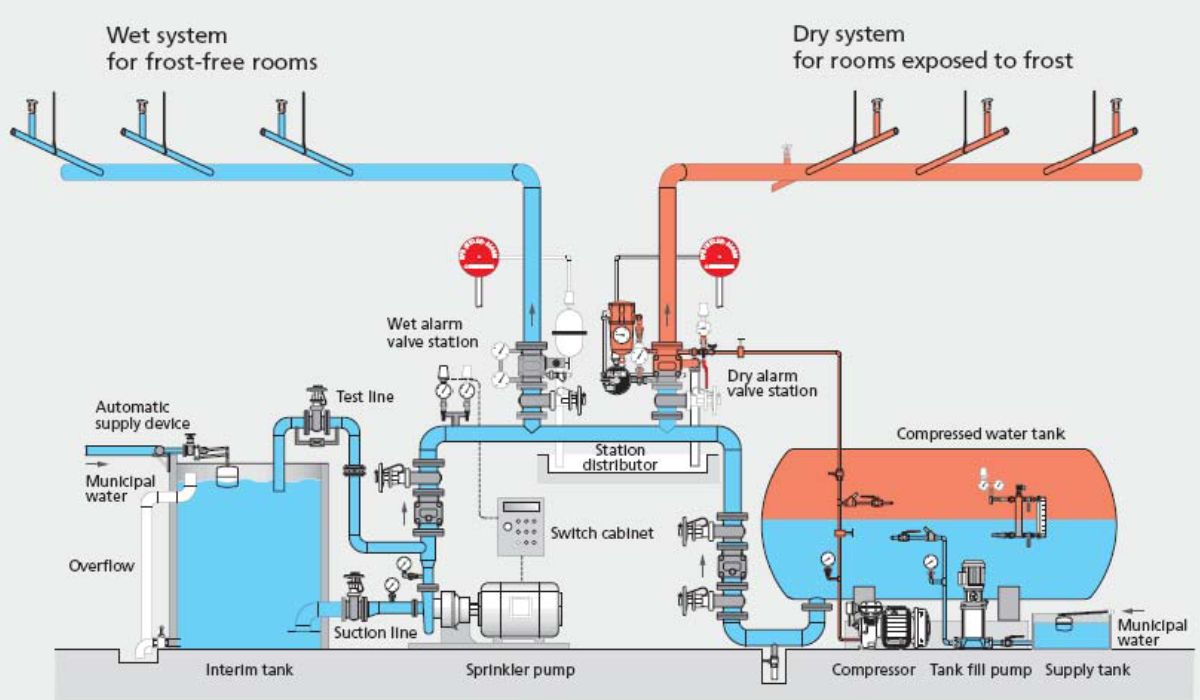

Active Fire Suppression Systems

Active fire suppression acts fast to control fires. Systems detect heat, smoke, or flame and then take action. Here are popular choices:

- Water Sprinklers: Deploy water to cool down and douse flames.

- Gas Suppression: Uses inert gases to suffocate the fire.

- Chemical Agents: Extinguish fires by removing heat or reducing oxygen.

- Fire Extinguishers: Allow manual intervention in early fire stages.

These systems often connect to alarms that alert nearby people. Maintenance checks ensure they work at crucial moments.

Passive Fire Protection Measures

Passive protection stops fire spread without human or system aid. Materials and building design play major roles. Key elements include:

- Fire-rated Insulation: Slows down fire spread, safeguarding the structure.

- Sealed Penetrations: Barriers prevent fire traveling via gaps or holes.

- Self-closing Doors: Close automatically to contain fire.

- Intumescent Seals: Expand when heated, ensuring door closure.

Combining active and passive measures provides comprehensive fire safety in freezers. Regular inspections and updates keep these systems effective. Safety should be the top priority in any freezing operation.

Innovative Solutions In Fire Detection

Fires in freezers can cause huge losses. The cold environment hides the heat and smoke.

Making the fire hard to detect. Innovative fire detection solutions are now vital for safety.

Advancements In Early Fire Detection Technologies

Fire detection technology has grown smarter and faster. Sophistication helps in early warnings.

- Thermal cameras catch temperature changes quickly.

- Aspiration systems pull air samples into a detector.

- Flame detectors spot fires in seconds.

These smart systems are set to alert before large fires happen. Swift detection saves lives and stock.

Importance Of Sensitivity In Smoke And Heat Detectors

High sensitivity in detectors is crucial. It allows catching a fire early, even in a freezer.

| Sensitivity | Importance |

|---|---|

| Smoke detection | Higher sensitivity means catching smoke faster. |

| Heat detection | Fast response to even small temperature rises. |

Sensitive detectors give time for quick action, reducing damage. Ensure delicate calibration for accuracy.

Fire Suppression Agents Suitable For Freezers

Fire Suppression Agents Suitable for Freezers are critical for ensuring safety in cold storage areas where traditional fire systems might fail. Optimal solutions must perform in extreme temperatures, safeguarding both the stored goods and the structural integrity of the freezer.

Using Dry Chemicals

Dry chemicals stand out as a go-to choice for freezer fire suppression. These non-conductive powders quickly smother flames. They remain unaffected by low temperatures, making them a reliable safety measure.

- ABC powder: Versatile and widely used

- BC powder: Focuses on liquid and gas fires

- Purple K: Efficient for oil or gas-based fires

Effective Liquid Suppression Options

Liquid fire suppression agents work well in freezers by rapidly cooling and extinguishing fires.

| Agent | Use-case | Benefits |

|---|---|---|

| Aqueous Film-Forming Foam (AFFF) | Flammable liquid fires | Creates a barrier against oxygen |

| Water Mist | Varied fire types | Minimal water damage |

| Antifreeze Agents | Preventing re-ignition | Prevents freezing of suppression liquids |

Credit: www.amazon.com

Best Practices For Freezer Fire Safety

Maintaining fire safety in freezers is crucial to protect products and people. The extreme cold combined with electrical components can pose unique hazards. Implementing best practices for freezer fire safety keeps these risks at bay. Prepare through regular assessments and clear emergency protocols. Let’s explore how.

Regular Risk Assessments And Audits

Conduct thorough checks to ensure a safe freezer environment.

- Inspect wiring and electrical outlets

- Assess the condition of insulation materials

- Verify the integrity of door seals and latches

- Check for the buildup of ice that may conceal faults

- Review storage methods to avoid flammable material build-up

Document findings and address issues promptly. Use a table to track improvements:

| Date | Issue Identified | Action Taken | Follow-Up Date |

|---|---|---|---|

| 01/04/2023 | Loose wiring in unit 5 | Secured wiring | 07/04/2023 |

Training Staff For Emergency Protocols

Knowledgeable staff can prevent fires and respond swiftly if one starts.

- Introduce fire risks specific to freezers

- Teach correct use of fire extinguishers

- Train in evacuation and headcount procedures

- Conduct regular fire drills

- Make emergency contacts easily accessible

Ensure all personnel are confident in these protocols. Update training with changes in freezer usage or staff.

Case Studies Of Fire Protection In Action

In this deep-dive, we spotlight fire protection strategies within sub-zero environments. With real-world examples, these case studies highlight vital lessons and triumphant tactics in safeguarding freezer facilities against fires.

Success Stories From Freezer Facilities

Diligent planning and cutting-edge systems yield success in fire protection. The stories below showcase effective defenses:

- The Ice-Co Mega Freeze: State-of-the-art sprinkler technology extinguished a fire quickly, preventing product loss.

- Quick Response Saves Inventory: At Frosty Storage, an alert team activated suppression systems, stopping a fire with minimal damage.

- Regular Checks Matter: Undetected electrical faults sparked a blaze; now, businesses emphasize routine inspections.

- Training Saves Lives: Staff training proved its worth during a rapid evacuation, underscoring its importance.

-

Lessons Learned from Past Freezer Fires: H3 heading

Lessons Learned From Past Freezer Fires

Past incidents teach crucial strategies for future safety. These lessons stem from real events:

Credit: www.homedepot.com

Future Of Fire Protection In Cold Storage

The future of fire protection in cold storage is poised for transformation. Emerging solutions promise enhanced safety, efficiency, and sustainability. Innovations are key to preventing disasters and limiting damage if a fire does occur. Here, we explore the cutting-edge advancements and eco-friendly practices shaping fire safety in freezers.

Emerging Technologies To Watch

Cold storage facilities look for new ways to improve fire safety. Future-focused technologies stand out.

- Smart Detection Systems: These use sensors to identify fire risks quickly.

- Advanced Suppression Solutions: These target fires without disrupting the cold environment.

- Robotics: Robots can fight fires in ultra-cold conditions where humans can’t.

- Aerosol Suppression: This technology extinguishes fires without water damage.

Integrating Fire Protection With Sustainable Practices

Fire safety must work with the planet, not against it. The newest systems use fewer resources and reduce environmental impact.

| Practice | Benefits |

|---|---|

| Waterless Suppression: | Conserves water and reduces runoff. |

| Green Agents: | Use materials that don’t harm the ozone layer. |

| Recyclable Materials: | For constructing safe and sustainable facilities. |

| Energy-Efficient Design: | Lowers power consumption for fire protection systems. |

Frequently Asked Questions On Fire Protection In Freezers

What Type Of Walk In Freezers Require Fire Sprinklers?

Walk-in freezers larger than 300 square feet often require fire sprinklers. Local building codes and regulations ultimately determine the necessity for sprinklers based on size and usage.

How Do I Keep My Fire Suppression System From Freezing?

To prevent your fire suppression system from freezing, ensure it’s properly insulated, maintain a minimum room temperature above freezing, utilize antifreeze solutions when applicable, regularly inspect for leaks, and conduct routine maintenance checks.

At What Temperature Do Fire Sprinklers Burst?

Fire sprinklers typically activate at temperatures between 135 to 165 degrees Fahrenheit (57 to 74 degrees Celsius).

What Type Of Sprinkler System Is Recommended For Cold Storage?

Dry sprinkler systems are best for cold storage to prevent pipe freezing and water damage. They use pressurized air in the pipes, which keeps water out until activated.

Conclusion

Safeguarding your freezer spaces is critical for business continuity and safety. Opting for advanced fire protection methods can be a game-changer. Remember, prevention is key; regular maintenance and updated systems save lives and assets. Protect your cold storage; secure your peace of mind.

Stay vigilant, stay safe.

I’m Abdus Sobur, a highly skilled and professional Fire Safety Officer with a passion for safeguarding lives and property. Over the course of my career, I’ve conducted numerous successful fire safety audits, earning a reputation for excellence in ensuring public safety.

In addition to my role as a Fire Safety Officer, I’m also dedicated to raising awareness about the importance of fire safety. Through my blog, I share insights into the functions of different fire safety equipment, aiming to empower individuals with the knowledge they need to protect themselves and their communities.

I’m driven by a deep commitment to promoting fire safety awareness and preventing fire-related incidents.