A dry pipe sprinkler system air compressor maintains system pressure to prevent water from entering the pipes until needed. It activates the sprinklers during a fire by releasing the air, which opens the water valve.

Dry pipe sprinkler systems offer fire protection in places where water could freeze, like unheated buildings or outdoor areas. The air compressor plays a crucial role by keeping the pipes dry until a fire’s heat triggers the system. These systems rely on pressurized air or nitrogen, which holds the main water valve closed.

Upon detecting a significant temperature increase, the air pressure drops, the valve releases, and water rushes into the pipes to extinguish the fire. This arrangement minimizes the risk of water damage and pipe bursts due to freezing, providing an effective fire suppression solution for cold environments or spaces with temperature fluctuations. The reliability of a dry pipe system heavily relies on the consistent performance of its air compressor.

Introduction To Dry Pipe Sprinkler Systems

Imagine a fire breaking out in a place filled with valuable items or in very cold temperatures. A Dry Pipe Sprinkler System comes into action. Unlike traditional systems, it uses air or nitrogen in the pipes. When a fire happens, the air gets released first. Then water rushes in to stop the fire. This system protects buildings where water could freeze.

Purpose And Environments

Dry Pipe Sprinkler Systems serve a special purpose. They fit in places that face cold climates. These places cannot have water in the pipes all the time. The systems are perfect for:

- Unheated warehouses

- Outdoor exposed areas

- Parking garages

- Freezers and cold storage facilities

Buildings with valuable things like art also benefit. They keep the art safe from accidental water damage.

Comparison With Wet Pipe Systems

| Dry Pipe Systems | Wet Pipe Systems |

|---|---|

| Air-filled pipes | Water-filled pipes |

| Good for freezing temperatures | Not suitable for cold environments |

| Delayed water release | Instant water release |

| Protection from water damage | Potential accidental water damage |

The main difference lies in the response to fire. Dry Pipe Systems take longer to react since air must exit first. Wet Pipe Systems quickly release water. Knowing the right system for a specific environment ensures maximum safety.

Core Components Of A Dry Pipe System

Understanding the core components of a dry pipe sprinkler system is crucial for safety. It ensures prompt fire suppression during emergencies. Such systems are ideal for environments at risk of freezing. Let’s explore the critical elements that make these systems reliable.

Dry Pipe Valve

The dry pipe valve is the heart of the system. It separates pressurized air from the water supply. Upon detecting a fire, the valve releases, allowing water to flow through the piping and extinguish the flames.

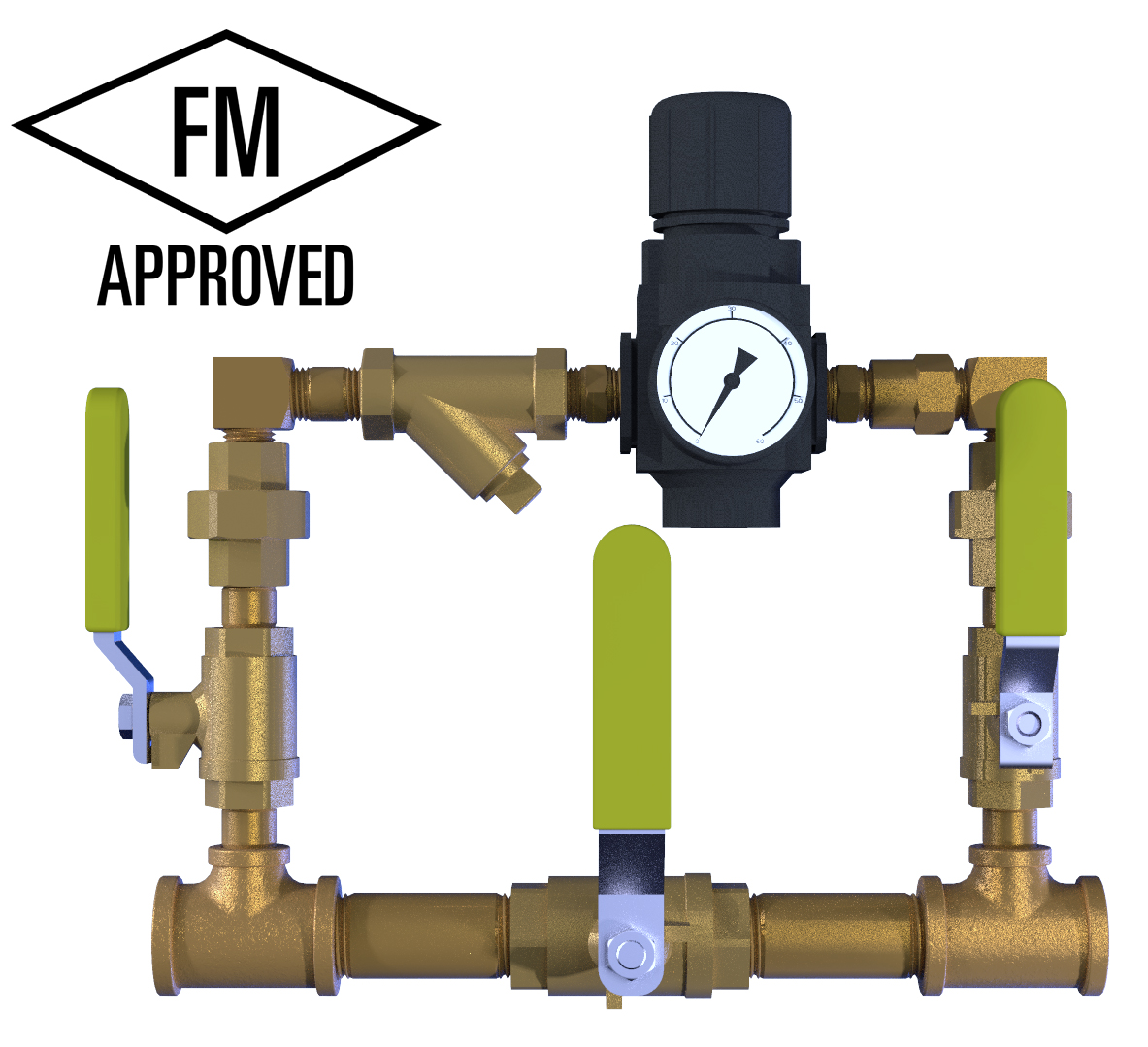

Air Compressor Essentials

A robust air compressor maintains system pressure. It fills the piping with air that holds the dry pipe valve closed. Proper compressor function is vital to avoid false activations or delays.

- Must match the system’s size

- Regular maintenance is critical

- Automatic and manual controls

Piping And Sprinkler Heads

Piping networks transport water to the sprinkler heads. These networks must be free of blockages or leaks. Different types of heads are used depending on the area’s needs.

| Sprinkler Head Type | Area of Use |

|---|---|

| Standard | General spaces |

| Extended Coverage | Larger areas |

| Quick Response | High-risk zones |

The Role Of The Air Compressor

Dry pipe sprinkler systems depend on air compressors. This vital component keeps the system ready to douse fires. An air compressor’s job in a dry pipe system is twofold: maintaining air pressure and activation during a fire. Let’s explore why they’re so crucial.

Maintaining Air Pressure

A dry pipe sprinkler system’s pipes aren’t filled with water. Instead, they contain pressurized air. The air compressor must maintain this pressure to prevent water from entering the pipes. Here’s how it works:

- The compressor kicks in when air pressure falls.

- It pumps air into the pipes to keep the right pressure level.

- This pressure holds back the water at the main valve.

- Regular checks ensure the compressor is working well.

Activation In Case Of Fire

During a fire, the air pressure in the pipes drops as the sprinkler heads open. Here’s what happens next:

- The air escapes and the pressure falls.

- This drop signals the main valve to open.

- Water rushes into the pipes to fight the fire.

- The air compressor stays inactive during this phase.

The air compressor has a pivotal role before and after a fire.

Your dry pipe sprinkler system stays on guard, thanks to the air compressor. Proper maintenance and operation of the air compressor ensure full-time readiness against fire hazards. Remember, the right air pressure is key to system efficiency and safety.

Selecting The Right Air Compressor

Fire safety matters. Dry pipe sprinkler systems keep buildings safe. But, they need air compressors. An air compressor powers the system. It fills pipes with air. It stops water from freezing. Selecting the right one is crucial.

Size And Capacity Considerations

The right size matters. It ensures efficiency. Too small, and it won’t do its job. Too large, and it wastes energy. Always match the compressor to the system’s requirements. Consider these points:

- System Volume: How big is the space? Bigger spaces need bigger compressors.

- Air Pressure Requirements: More pressure means a more powerful compressor is needed.

- Usage Frequency: Used often? Get a durable one.

Types Of Air Compressors For Dry Pipe Systems

Different compressors suit different systems. Know the types:

| Type | Features | Best For |

|---|---|---|

| Piston Type | High pressure, reliable | Smaller systems |

| Rotary Screw | Continuous flow, quieter | Larger, industrial spaces |

| Scroll | Energy-efficient, low maintenance | Mid-sized installations |

Each compressor has unique benefits. Assess the system. Then, pick the right type.

Installation Best Practices

Proper installation is critical for a Dry Pipe Sprinkler System Air Compressor. It drives the system’s efficiency. Let’s explore the key practices for a smooth, reliable setup.

Professional Installation

Expertise makes a vast difference in the installation. Professionals ensure precise setup and functionality.

- Choose certified technicians who understand the nuances of these systems.

- Ensure they have a track record of successful installations.

- A thorough inspection pre-installation can prevent future issues.

- Proper calibration of the air compressor is crucial for the best performance.

Compliance With Safety Standards

Adherence to safety standards is non-negotiable. It guarantees the system’s potential to protect.

- Follow National Fire Protection Association (NFPA) codes strictly.

- Local regulations may have additional requirements. Adherence is needed.

- Regularly review manufacturer’s guidelines for specific appliance nuances.

- Failure to comply may lead to system underperformance or legal complications.

Maintenance And Servicing

Regular maintenance and servicing play a pivotal role in the longevity and reliability of dry pipe sprinkler system air compressors. Proper care ensures they operate smoothly and effectively respond in case of a fire. This section dives into the essential routine checks, and troubleshooting common issues for optimal performance and safety.

Routine Checks

Maintaining a dry pipe sprinkler system involves systematic checks. Follow these steps:

- Inspect pressure levels – Confirm they meet the system’s specifications.

- Examine for corrosion – Look for signs on pipes and the compressor unit.

- Check for leaks – Use a soapy water solution on pipes and joints.

- Drain moisture – Perform weekly to prevent freezing and damage.

- Listen for unusual sounds – Noises can signal internal issues.

Record all observations for reference during professional inspections.

Troubleshooting Common Issues

Here are troubleshooting steps:

| Issue | Step |

|---|---|

| Low pressure alerts | Check for open valves or leaks, and reset the compressor. |

| Corrosion | Contact a professional for repair or replacement parts. |

| Weird noises | Switch off the system and seek immediate professional help. |

| Frequent moisture drainage | Adjust the dryer or verify the draining system’s efficiency. |

Resolve these issues swiftly to prevent system failure.

Understanding Air Pressure

Understanding Air Pressure in a dry pipe sprinkler system is crucial for its efficiency and safety. Dry pipe systems rely on air, not water, to be ready for action in case of a fire. It’s the air that keeps the water behind a valve. Only when a fire triggers the system does the air escape, allowing water to fight the flames. Let’s dive into how to manage the air pressure in these systems to ensure they function correctly when needed.

Normal Operating Pressures

Dry pipe sprinkler systems have a range of pressures for normal operation. This pressure keeps water back and waits for a fire sign. Each system may have a different normal pressure. It’s often between 40 to 60 psi (pounds per square inch). We should always check the manufacturer’s guide to know the right pressure for our system.

| System Size | Normal Pressure Range |

|---|---|

| Small | 40 psi |

| Medium | 50 psi |

| Large | 60 psi |

Adjusting System Pressure

To adjust system pressure, you must follow a few steps. This will make sure your system responds well to fires. First, locate the control panel. This is the brain of your system. Use a wrench to adjust the valve and watch the pressure gauge. Change the pressure slowly and carefully. It’s a delicate balance to maintain. Make sure not to go below or above the normal operating range. After adjusting, remember to lock the valve back in place.

- Locate the control panel

- Use a wrench to adjust the valve

- Monitor the pressure gauge

- Keep within the normal range

- Lock the valve after adjusting

System Testing And Inspection

Dry Pipe Sprinkler Systems need regular check-ups to work well. These check-ups and tests keep the system ready to fight fires. Like a check-up at a doctor, tests find problems early. This means smaller, easier fixes. Keeping your system in top shape is vital.

Frequency Of Inspections

To keep your Dry Pipe Sprinkler System in good shape, routine tests are a must. The National Fire Protection Association (NFPA) gives the rules for these tests. Systems need different tests at varied times. The rules are easy to follow:

- Weekly: Check air pressure and gauges.

- Monthly: Inspect air compressor and power supplies.

- Quarterly: Look at low-pressure alarms and check valve operations.

- Yearly: Full system test by a professional.

Each one keeps your system effective and ready to stop fires.

Record Keeping And Documentation

Writing down what happens during inspections is as important as the check-ups. Good records help track the system’s health. They also prove your sprinkler system gets the care it needs. Here’s how to manage records:

- Keep a log: Write down all test results and fixes.

- Save documents: Store all reports from inspectors.

- Update frequently: Add new information right after tests.

- Follow NFPA codes: Use their guidelines for record details.

This makes sure your system gets honest, top-notch care.

Upgrades And Retrofitting

Keeping fire safety systems at peak performance is crucial for building safety.

Upgrading and retrofitting a Dry Pipe Sprinkler System Air Compressor ensures optimal operation and compliance with the latest safety standards.

When To Consider Upgrades

- Obsolescence: Air compressors over a decade old may need replacement.

- Performance Issues: Frequent breakdowns signal the need for an upgrade.

- Regulation Changes: New codes may require system updates.

- Expansion: Building changes can mean system adjustments.

Modern Advancements In Dry Pipe Systems

Technological improvements make modern systems more reliable and efficient.

| Feature | Benefit |

|---|---|

| Smart Tech: | Remote monitoring for quick issue detection. |

| Energy Efficiency: | Lower operating costs and environmental impact. |

| Variable Speed: | Adjustable airflow reduces wear and improves longevity. |

Credit: cairecompressors.com

Cost-benefit Analysis

Exploring the worth of a Dry Pipe Sprinkler System Air Compressor involves careful costing. Companies find it vital to weigh initial outlay against future monetary gains. Firm owners often seek data on the financial aspects before investing. Here is a breakdown.

Initial Investment

The upfront cost of a Dry Pipe Sprinkler System Air Compressor spans several factors:

- Unit Price: Compressor costs vary by size and power capacity.

- Installation Fees: Professional setup services add to the initial expense.

- Accessories: Additional elements like alarms or valve enclosures may be necessary.

Despite these costs, the compressor’s role in safety can’t be underplayed. It’s an investment in protection.

Long-term Savings And Benefits

Adopting a compressor for your sprinkler system promises long-term payoff:

| Benefit | Description |

|---|---|

| Reduced Water Damage | Systems activate only when needed, lessening chance accidents. |

| Low Maintenance | Fewer moving parts mean less frequent servicing. |

| Insurance Discounts | Many insurers offer breaks for improved safety measures. |

| Longevity | Lasting equipment defers replacement costs. |

Owners also notice indirect savings through enhanced property integrity and occupant safety. The compressor turns out to be a strategic financial decision.

Regulatory Compliance And Standards

Regulatory Compliance and Standards play a crucial role in the safety and efficiency of dry pipe sprinkler systems. Understanding and adhering to these regulations ensures your system functions correctly. Installers, inspectors, and building owners must follow the latest codes.

National Fire Protection Association (nfpa) Guidelines

Dry pipe sprinkler systems must meet specific guidelines set by the NFPA. The NFPA provides detailed standards. It covers system design, installation, and maintenance. These guidelines aim to prevent system failures and ensure fast action during fires.

- NFPA 13: Standard for Installation.

- NFPA 25: Standard for Inspection, Testing, and Maintenance.

- Proper air pressure levels and dry system response times are outlined.

Local Fire Codes And Regulations

In addition to NFPA standards, local fire codes mandate compliance. They can vary from city to city. Always check local codes to ensure your system meets all necessary regulations. They may have additional inspection and testing requirements.

| Requirement | Purpose | Frequency |

|---|---|---|

| Inspections | System functionality | Annual/Biannual |

| Maintenance | Operational efficiency | As needed/Post-activation |

| Testing | Code compliance | Quarterly/Annually |

Consult with fire safety experts or authorities having jurisdiction. This ensures your dry pipe sprinkler system air compressor fully complies with both NFPA guidelines and local fire codes. Compliance guarantees the safety and functionality of your fire suppression efforts.

Credit: unitedfiresystems.com

Environmental Considerations

When thinking about fire safety, it’s essential to look at our planet’s health too. Dry pipe sprinkler systems rely on air compressors, and these can affect our environment. Let’s dive into the details and explore eco-friendly options.

Impact On The Environment

Dry pipe sprinkler systems are crucial for freezing climates. Traditional air compressors in these systems can use a lot of energy. More energy means more carbon emissions.

These systems discharge nitrogen or air. They can leak, leading to energy waste. Proper maintenance reduces leaks and saves energy.

Eco-friendly Alternatives

Choosing green options is important. Let’s consider some ways to make dry pipe sprinkler systems kinder to our planet.

- Energy-efficient compressors: These use less power and cut emissions.

- Solar-powered units: They harness the sun’s energy, slashing carbon footprints.

- Smart monitoring: This tech spots leaks fast, saving air and energy.

By opting for eco-friendly air compressors, we safeguard both people and the environment.

Case Studies

Dry pipe sprinkler systems offer crucial protection against fires in environments prone to freezing. Through case studies, we learn from both successes and failures. These real-world examples provide valuable insights into how air compressor units in dry pipe systems can make or break safety outcomes.

Success Stories

These narratives highlight the importance of proper installation and maintenance.

- A large storage facility in Minnesota attributes its safety to a well-maintained dry pipe system. The temperatures often plummet, but regular checks ensured functionality.

- In Alaska, a remote health clinic evaded disaster thanks to their dry pipe sprinkler system. A fire broke out, but the swift response of the sprinkler system prevented a large-scale calamity.

Lessons From System Failures

Mistakes and oversights can lead to system failures.

| Incident | Cause | Lesson |

|---|---|---|

| Warehouse fire | Inadequate air pressure | Monitor air pressure regularly. |

| School sprinkler delay | Compressor power failure | Implement backup power solutions. |

Each case teaches vital lessons on preparedness and the value of attention to detail.

Credit: blog.qrfs.com

Future Of Dry Pipe Systems

Imagine living in a world where safety and technology meld seamlessly together. This world is not far off, especially when it comes to dry pipe sprinkler systems. Modern air compressors have already transformed these systems, ensuring buildings are safer than ever. But what does the future hold? The potential for innovation and smart system integration suggests we are just seeing the beginning.

Technological Innovation

Technological advances continue to push the boundaries for dry pipe sprinkler systems. Future air compressors are expected to be:

- More efficient, using less energy to operate.

- Quicker to respond to pressure changes in the system.

- Equipped with superior monitoring capabilities to predict issues before they arise.

Revolutionary materials could enable systems to endure harsher environments with minimal maintenance. Innovation in compressor design is poised to make these units smaller, quieter, and more environmentally friendly.

Smart System Integration

The integration of smart technology is revolutionizing dry pipe systems. Future systems will likely include:

- Real-time alerts to mobile devices for instant status updates.

- Automated testing routines reducing the need for manual checks.

- Connection to building management systems for coordinated safety strategies.

With these smart integrations, sprinkler systems will communicate with other safety measures in a building, creating a cohesive protective network. The dry pipe air compressor will not just activate the system but also contribute to a building’s overall safety intelligence.

Frequently Asked Questions Of Dry Pipe Sprinkler System Air Compressor

Does A Dry Sprinkler System Need An Air Compressor?

Yes, a dry sprinkler system requires an air compressor to maintain pressure and prevent water from entering the pipes until needed.

What Is The Required Air Pressure For A Dry Pipe System?

The required air pressure for a dry pipe sprinkler system typically ranges between 10-20 psi (pounds per square inch). Always consult manufacturer specifications and local codes for precise requirements.

What Are The Disadvantages Of A Dry Pipe Sprinkler System?

Dry pipe sprinkler systems experience delayed water delivery, are more complex to install and maintain, and can face increased corrosion, potentially leading to more frequent repairs and higher costs.

What Triggers Dry Pipe Sprinkler System?

A dry pipe sprinkler system activates when a significant drop in air pressure within the pipes is detected, typically caused by a fire’s heat.

What Is A Dry Pipe Sprinkler System?

A dry pipe sprinkler system is designed for areas where water can freeze, utilizing pressurized air in the pipes that releases water when a fire is detected.

How Does The Air Compressor Function?

An air compressor maintains adequate pressure to keep the dry pipe valve closed, preventing water from entering the sprinkler piping until needed.

Conclusion

Ensuring your dry pipe sprinkler system operates flawlessly is crucial for fire safety. Regular inspection and maintenance, including air compressor checks, is essential. Remember, a well-maintained system can mean the difference between minor damage and a catastrophic event. Protect your property; prioritize your sprinkler system’s health.

I’m Abdus Sobur, a highly skilled and professional Fire Safety Officer with a passion for safeguarding lives and property. Over the course of my career, I’ve conducted numerous successful fire safety audits, earning a reputation for excellence in ensuring public safety.

In addition to my role as a Fire Safety Officer, I’m also dedicated to raising awareness about the importance of fire safety. Through my blog, I share insights into the functions of different fire safety equipment, aiming to empower individuals with the knowledge they need to protect themselves and their communities.

I’m driven by a deep commitment to promoting fire safety awareness and preventing fire-related incidents.