A backflow preventer in a fire sprinkler system prevents contamination of the water supply. It ensures water flows only in one direction during firefighting.

Ensuring the safety and reliability of fire sprinkler systems is paramount. A backflow preventer plays a critical role in maintaining the integrity of both the sprinkler system and the public water supply. This device is essential in avoiding the reverse flow of potentially contaminated water, which could cause serious safety hazards.

With fire hazards looming as a constant threat, the installation of a proper backflow preventer not only complies with safety regulations but also protects communities. These systems are engineered to automatically deliver water in the event of a fire, and the backflow preventer ensures this water remains uncontaminated, aiding firefighters effectively. It is a crucial component that maintains the purity and pressure essential for fire suppression systems to function correctly.

Introduction To Backflow Preventer Systems

Backflow preventer systems are critical in any building’s fire safety plan. They keep water moving in the right direction during a fire. This means they stop dirty water from going back into the clean water supply. Let’s explore why they are important and how they work.

Importance In Fire Safety

A backflow preventer in a fire sprinkler system keeps the water safe and ready. It makes sure that the water that fights fires doesn’t mix with the drinking water. This keeps everyone healthy and safe.

Basic Functionality

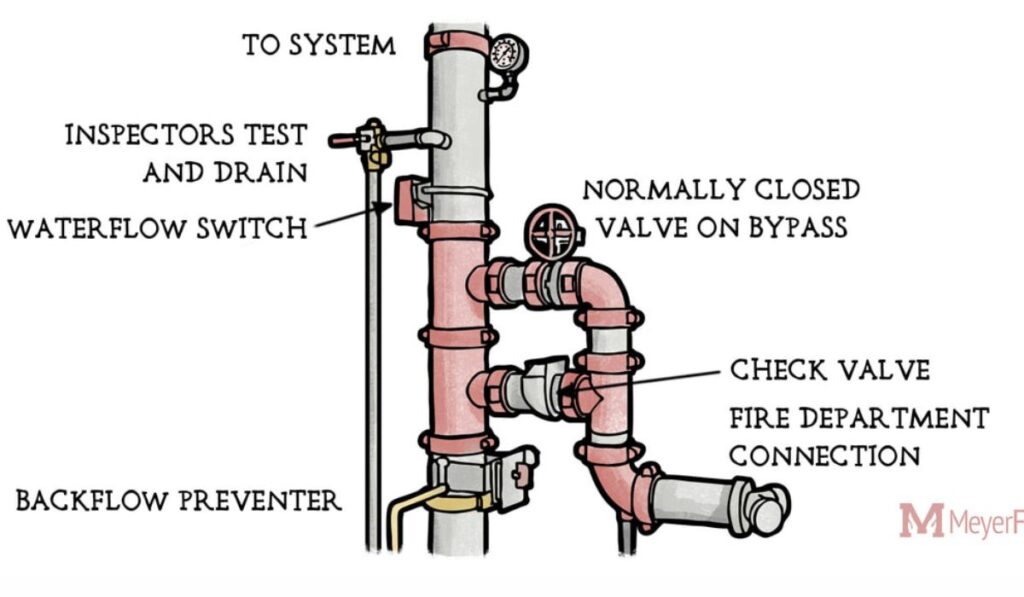

- The device closes to stop water from going backwards.

- It opens to let water flow into the sprinkler system when needed.

- A check valve system makes sure water moves in one direction.

Fire Sprinkler Systems And Backflow Prevention

Fire sprinkler systems are guardians of our buildings, jumping into action during a fire.

They save lives and protect property. But there’s a silent hero in these systems: the backflow preventer.

It keeps drinking water safe from contamination. Let’s dive into how it teams up with sprinklers.

Role In Fire Suppression

A backflow preventer’s job is simple, yet crucial. It stops water from reversing

direction and flowing back into the public water supply. This reverse flow can happen during a fire event,

which may introduce harmful contaminants.

- Keeps drinking water clean: By preventing contamination.

- Ensures fire sprinkler readiness: Maintains the system’s integrity.

Integration With Sprinklers

In fire sprinkler systems, backflow preventers are not a standalone feature.

They’re integrated with the entire setup. This ensures that when a fire activates the sprinkler,

the water used to extinguish the fire doesn’t compromise the drinking supply.

| Component | Function |

|---|---|

| Fire Sprinkler Heads | Disperse water during a fire. |

| Backflow Preventer | Stops contaminated water from returning to clean water supply. |

| Pipes | Carry water to the sprinkler heads. |

Types Of Backflow Preventers

Backflow preventers are a crucial component of fire sprinkler systems. These devices ensure contaminated water does not flow back into the clean water supply. Understanding the various types of backflow preventers can help you decide which is best for a fire sprinkler system.

Pressure Vacuum Breakers

Pressure vacuum breakers (PVBs) are the simplest and most commonly used backflow preventers. Easy to install and maintain, PVBs are ideal for systems that require protection against back siphonage, but not back pressure.

- Keep pipes from freezing – Install in areas that will not drop below freezing temperatures.

- Routine checks – Test annually to ensure functionality.

Double Check Valves

Double check valves (DCVs) contain two check valves sequenced together. This doubles the protection against backflow. Suitable for low to medium hazard conditions, DCVs work for both back siphonage and back pressure.

| Features | Benefits |

|---|---|

| Twin valves | Enhanced security |

| Horizontal or vertical installation | Flexible fitting |

Reduced Pressure Zone Assemblies

Reduced Pressure Zone Assemblies (RPZAs) offer the highest level of protection. These devices are suitable for high hazard situations. RPZAs have a relief valve that opens to the atmosphere between two independently acting check valves.

- Protects against both back siphonage and back pressure.

- Has a special relief valve to handle severe backflow conditions.

Compliance And Standards

Ensuring the safety and functionality of fire sprinkler systems is crucial. A critical part of this system is the backflow preventer, which keeps potable water supplies from contamination due to reverse flow. Compliance with local and national standards is not only mandatory but essential for system integrity and public safety. Let’s delve into the codes and guidelines that govern these systems.

Local Codes And Regulations

Adherence to local codes is imperative for all fire sprinkler installations.

Local jurisdictions may have specific requirements that dictate the type, installation, and maintenance of backflow preventers.

- Check with the local building department.

- Obtain necessary permits.

- Schedule required inspections.

Non-compliance can lead to penalties and potentially dangerous situations.

National Fire Protection Association (nfpa) Guidelines

The NFPA provides comprehensive guidelines for fire sprinkler systems.

- Review NFPA standards 13, 13D, and 13R for residential and commercial systems.

- Understand NFPA 25 for inspection, testing, and maintenance.

- Implement NFPA standards 291 for water flow testing.

Stay current with NFPA updates to avoid non-compliance.

Installation Best Practices

Welcome to the comprehensive guide on backflow preventer fire sprinkler system installation. High safety standards during installation are vital. Follow these industry best practices to ensure your backflow preventer works flawlessly.

Professional Installation

Trust only certified professionals to install your backflow preventer. An expert understands local codes and manufacturer instructions. They ensure your sprinkler system functions as intended. To verify credentials, ask for certifications and references before hiring.

Strategic Placement For Efficacy

Correct placement is crucial for a backflow preventer. Install the device in an easily accessible area for maintenance and testing. Avoid places prone to freezing temperatures to prevent damage. Also, ensure the backflow preventer is above ground to facilitate proper drainage.

Following these installation best practices will help maintain the integrity and reliability of your fire sprinkler system. Secure your property by adhering to these strategies for installation. A professional installation and strategic placement cement the foundation of an effective fire defense mechanism.

Maintenance And Testing Procedures

Keeping fire sprinkler systems in perfect working order is vital for safety. Regular maintenance and testing are essential. This ensures that, in an emergency, the backflow preventer and the entire system function correctly. Let’s dive into the procedures that help protect your property.

Routine Inspection

Simple checks can spot common issues. Follow a routine inspection schedule:

- Examine the backflow preventer for any visible damage.

- Check for leaks around the valves and pipes.

- Ensure accessibility is clear from obstructions.

- Look for signs of rust or wear on device components.

Visual inspections should be done monthly. This keeps the system reliable.

Professional Testing And Certification

A certified technician must test backflow prevention devices annually. This is mandatory by law. It safeguards the water supply. The steps include:

- Shutting down the system carefully.

- Inspecting all valves and connections.

- Using specialized tools to test backflow preventer function.

- Ensuring no reverse flow of water is possible.

Certification documents the state of the system. Keep records for at least five years.

| Action | Frequency |

|---|---|

| Visual Checks | Monthly |

| Professional Tests | Annually |

Follow this guide rigorously. Protect your property with a compliant fire sprinkler system.

Common Issues And Solutions

A Backflow Preventer Fire Sprinkler System is crucial for safety. Like all systems, it faces challenges. Understanding these issues helps in maintenance. Below, find common problems and their fixes.

Backflow Leaks

Backflow Leaks

Leaks in a backflow preventer can disrupt system integrity. They are usually due to worn-out parts or high pressure. Regular inspections help identify leaks early. Replacing faulty components often solves this issue.

Valve Malfunctions

Valve Malfunctions

Valve issues can cause backflow malfunctions. Debris or wear and tear can be the culprit. Professional cleaning or replacing valves is the typical solution.

Freezing Conditions

Freezing Conditions

Freezing temperatures can damage a backflow preventer. Water inside can freeze and expand, leading to cracks. Insulation or heat tapes prevent freezing. Strategic heating solutions keep the system safe from icy conditions.

| Issue Type | Common Causes | Recommended Fixes |

|---|---|---|

| Backflow Leaks | Worn parts, high water pressure | Part replacement, pressure adjustments |

| Valve Malfunctions | Debris, wear and tear | Cleaning, valve replacement |

| Freezing Conditions | Low temperatures | Insulation, heat application |

- Regular inspections: Catch issues before they worsen

- Timely maintenance: Prevent costly repairs and ensure system reliability

- Professional consultation: Get expert advice for complex problems

- Inspect your backflow preventer regularly.

- Address leaks and valve issues promptly.

- Protect your system from freezing temperatures.