To size a fire pump, calculate the required flow rate and pressure. Use these values to select the appropriate pump.

Sizing a fire pump ensures your system meets safety standards and performs efficiently. Determine the needed flow rate, usually gallons per minute (GPM). This depends on the building’s size, occupancy type, and local fire codes. Next, calculate the required pressure, factoring in elevation changes and friction losses in the piping system.

Combine these two crucial metrics to select a pump that meets or exceeds the specifications. Proper sizing prevents inadequate water supply during emergencies, safeguarding property and lives. Accurate calculations and correct pump selection are essential for an effective fire protection system.

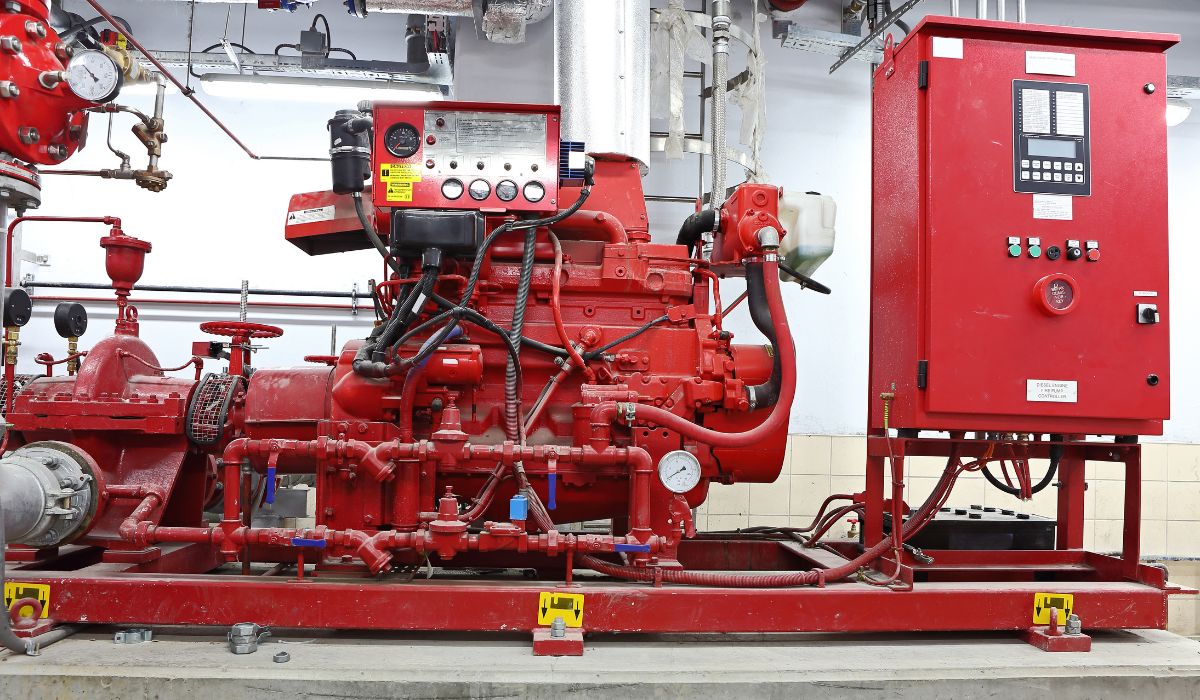

Introduction To Fire Pumps

Fire pumps are vital components in fire protection systems. They ensure a reliable water supply during emergencies. Understanding their purpose and types is essential for proper sizing.

Purpose And Importance

Fire pumps boost water pressure for fire suppression systems. They play a crucial role in maintaining safety in buildings. Without fire pumps, sprinklers and hoses may not function effectively. Ensuring the right size of a fire pump is essential for optimal performance.

Types Of Fire Pumps

There are several types of fire pumps to consider. Each type serves different needs and has unique features. Here are the primary types:

- Horizontal Split-Case Pump: Known for reliability and ease of maintenance.

- Vertical Turbine Pump: Ideal for water sources below ground level.

- End Suction Pump: Compact and cost-effective for small systems.

- Vertical Inline Pump: Space-saving and suitable for high-rise buildings.

Choosing the right type depends on the specific requirements of your system. Consider factors like the water source, building height, and system design.

Basic Principles Of Sizing

Sizing a fire pump correctly is crucial for ensuring safety. This process involves understanding flow rate and pressure requirements. Both factors are essential for effective fire suppression.

Flow Rate Requirements

Flow rate is the amount of water the pump must deliver. It is usually measured in gallons per minute (GPM). To determine the flow rate:

- Identify the areas that need protection.

- Calculate the total water demand for these areas.

- Consider the specific needs of each sprinkler system.

Use this simple formula: Total GPM = Area (sq ft) x Density (GPM/sq ft). This helps in estimating the required flow rate accurately.

Pressure Requirements

Pressure is the force needed to move water through the system. It is measured in pounds per square inch (PSI). To determine the pressure requirements:

- Evaluate the height of the building.

- Consider the friction losses in the pipes.

- Account for any additional pressure needed for the sprinkler heads.

A simple formula: Total PSI = Elevation Head + Friction Loss + Sprinkler Pressure. This ensures the pump delivers water effectively.

Here is a quick reference table for both flow rate and pressure:

| Component | Calculation | Units |

|---|---|---|

| Flow Rate | Area (sq ft) x Density (GPM/sq ft) | GPM |

| Pressure | Elevation Head + Friction Loss + Sprinkler Pressure | PSI |

Calculating Water Demand

Calculating water demand is essential for sizing a fire pump. This ensures the system can meet the requirements during a fire emergency. Let’s explore the key factors in this calculation.

Building Occupancy

Building occupancy affects water demand calculations. Different types of buildings need different amounts of water. For example, a residential building needs less water than a commercial building.

| Type of Occupancy | Water Demand (GPM) |

|---|---|

| Residential | 250-500 |

| Commercial | 500-1500 |

| Industrial | 1000-3000 |

It’s important to identify the occupancy type accurately. This ensures the fire pump can deliver the required water flow.

Fire Hazard Classification

Fire hazard classification also impacts water demand. Different fire hazards need different water supply rates. The National Fire Protection Association (NFPA) classifies hazards into three categories:

- Light Hazard: Small amounts of flammable materials. Examples: Offices, schools.

- Ordinary Hazard: Moderate amounts of flammable materials. Examples: Retail stores, parking garages.

- Extra Hazard: Large amounts of flammable materials. Examples: Chemical plants, warehouses.

Each classification has specific water demand rates:

| Hazard Classification | Water Demand (GPM) |

|---|---|

| Light Hazard | 100-250 |

| Ordinary Hazard | 250-500 |

| Extra Hazard | 500-1000 |

Proper classification ensures the fire pump meets the necessary water flow. This is crucial during emergency situations.

Understanding Pump Curves

Knowing how to size a fire pump is crucial. One key aspect is understanding pump curves. These curves help you see how the pump performs. They show the relationship between flow rate and pressure.

Reading Pump Curves

Pump curves are graphs. The X-axis represents the flow rate. The Y-axis shows the pressure. Each point on the curve indicates a different operating point.

Here is a simple table to explain:

| X-axis | Y-axis |

|---|---|

| Flow Rate (GPM) | Pressure (PSI) |

It’s important to match the pump’s performance with your needs. Look for the point where your required flow rate and pressure meet on the curve.

Interpreting Data

Interpreting the data on a pump curve involves several steps:

- Identify the required flow rate for your system.

- Find the corresponding pressure on the Y-axis.

- Check if the pump can handle this operating point.

Sometimes, you might need to adjust your requirements. Choose a pump that meets your needs without straining its capacity.

Selecting The Right Pump

Choosing the right fire pump is essential for safety. A well-sized pump ensures adequate water flow and pressure. This section will guide you through the key factors.

Centrifugal Vs. Positive Displacement

Centrifugal pumps are common in fire protection. They are efficient and easy to maintain. These pumps use a rotating impeller to move water. They are suitable for high-flow, low-pressure situations.

Positive displacement pumps move a set volume of water per cycle. They are ideal for low-flow, high-pressure applications. These pumps are precise and reliable.

| Type | Ideal Use | Advantages |

|---|---|---|

| Centrifugal | High-flow, Low-pressure | Efficient, Easy to maintain |

| Positive Displacement | Low-flow, High-pressure | Precise, Reliable |

Material Considerations

The material of the pump affects its durability. Cast iron is common and cost-effective. It resists wear and can handle various water conditions.

Bronze is another option. It offers excellent corrosion resistance. This makes it suitable for marine and coastal areas.

Stainless steel provides superior corrosion resistance. It is ideal for harsh environments but can be costly.

- Cast Iron: Durable, cost-effective, handles various water conditions.

- Bronze: Excellent corrosion resistance, ideal for marine areas.

- Stainless Steel: Superior corrosion resistance, suitable for harsh environments.

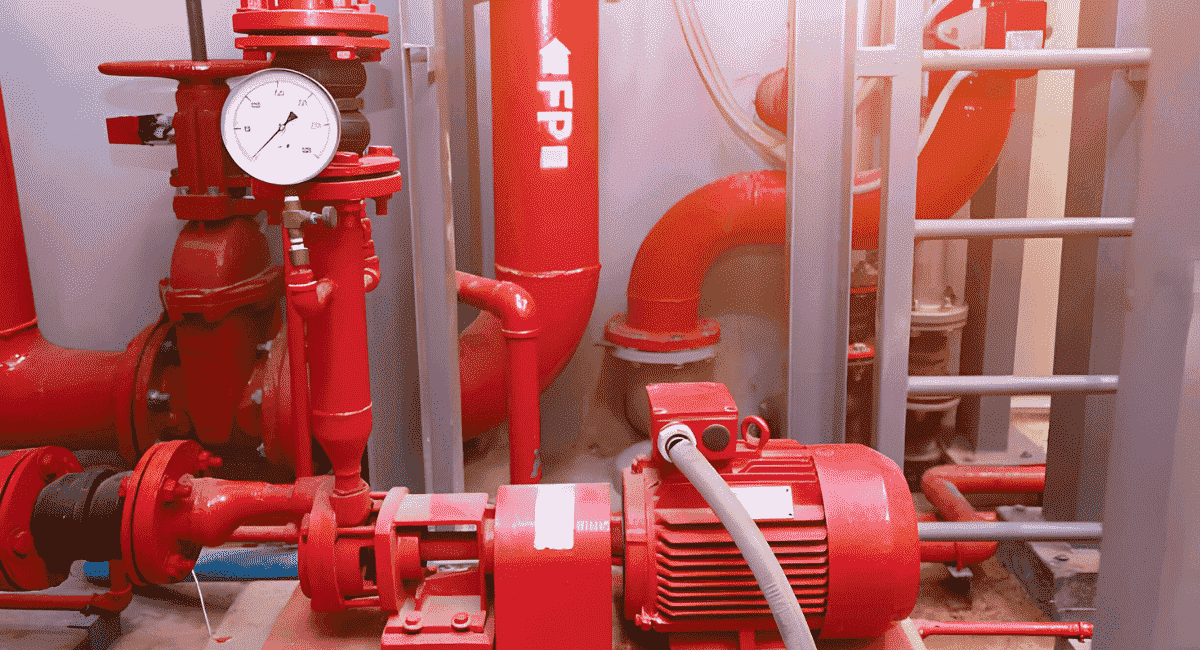

Installation Best Practices

Proper installation of a fire pump ensures its efficiency and reliability. Follow these best practices to make sure your fire pump operates correctly. Correct installation can prevent future issues and maintain safety.

Location And Placement

Choosing the right location is crucial. The fire pump should be in a dry, ventilated area. Ensure it is protected from extreme weather conditions. Place the pump on a solid, level surface.

Ensure there is enough space around the pump. This allows for easy maintenance and inspection. Keep the area free from obstructions.

Piping And Connections

Proper piping is essential for the fire pump’s performance. Use pipes that match the pump’s specifications. Ensure all connections are tight and leak-free.

Install isolation valves on both the suction and discharge sides. This helps in maintenance and emergency situations. Use flexible connectors to reduce vibration and noise.

| Piping Component | Best Practice |

|---|---|

| Suction Pipe | Ensure it is short and straight |

| Discharge Pipe | Install a check valve |

| Isolation Valves | Install on both sides |

| Flexible Connectors | Reduce vibration |

Maintenance And Testing

Proper maintenance and testing are crucial for ensuring the efficiency of your fire pump. Regular checks can prevent failures and ensure the pump operates when needed. This section focuses on key aspects of maintenance and testing.

Regular Inspections

Regular inspections help identify potential issues early. Inspecting the fire pump involves checking for leaks, unusual noises, and vibration. Ensure that the pump house is clean and free of clutter. Verify that the gauges and controls are functioning correctly. Inspect the electrical connections for wear and tear.

| Inspection Task | Frequency |

|---|---|

| Check for leaks | Weekly |

| Inspect gauges | Monthly |

| Test electrical connections | Quarterly |

Performance Testing

Performance testing ensures that the pump delivers the required water flow and pressure. Conduct a flow test to measure the pump’s output. Compare the results with the manufacturer’s specifications. Perform a churn test to check the pump at zero flow conditions. Record the results and address any discrepancies immediately.

- Start the pump and let it reach operating speed.

- Measure the flow rate using a flow meter.

- Compare the flow rate to the required specifications.

- Perform a churn test and record the pressure.

- Document all test results for future reference.

Regular maintenance and testing ensure your fire pump is always ready. It can save lives and property during an emergency. Always follow the manufacturer’s guidelines for maintenance and testing.

Common Mistakes To Avoid

Sizing a fire pump correctly is crucial. Many make mistakes that can affect safety and efficiency. Here are common mistakes to avoid.

Oversizing And Undersizing

Oversizing and undersizing are frequent errors. Oversizing a fire pump can lead to several problems:

- Higher installation costs

- Increased energy consumption

- Potential system damage due to high pressure

Undersizing a fire pump is equally problematic. It can result in:

- Insufficient water supply during a fire emergency

- Increased wear and tear on the pump

- Failure to meet fire safety standards

Ignoring Local Codes

Ignoring local codes is a critical mistake. Each area has specific fire safety regulations. Not following these can have severe consequences:

- Legal repercussions for non-compliance

- Increased risk of fire hazards

- Potential fines and penalties

Always check local fire safety codes. Ensure your fire pump meets all requirements. This step is vital for safety and compliance.

Advanced Sizing Techniques

Properly sizing a fire pump is crucial for safety and efficiency. Advanced techniques help ensure the pump meets all demands. Below, we explore two key methods: using software tools and considering future expansion.

Use Of Software Tools

Using software tools can simplify the fire pump sizing process. These tools analyze various factors, providing precise calculations. Here’s how they work:

- Input building specifications and fire protection requirements.

- The software processes data based on NFPA standards.

- It generates a detailed report with the recommended pump size.

Software tools save time and reduce human error. They offer a clear, accurate solution for fire pump sizing.

Considering Future Expansion

When sizing a fire pump, consider potential future expansions. This ensures the pump can handle increased demands later. Follow these steps:

- Estimate possible future water needs.

- Add a safety margin to current requirements.

- Select a pump with capacity for these extended needs.

Planning for the future avoids costly upgrades. It ensures the fire protection system remains effective over time.

Conclusion And Final Tips

Choosing the right fire pump size is crucial for building safety. This section offers final tips and a recap of key points to ensure you make the best decision.

Recap Of Key Points

- Understand Your Building’s Needs: Determine the water demand and fire risk.

- Calculate Water Flow and Pressure: Use accurate formulas for precise measurements.

- Consider System Design: Ensure compatibility with existing systems.

- Consult Professionals: Always seek expert advice for complex calculations.

- Regular Maintenance: Keep the fire pump in optimal condition through regular checks.

Additional Resources

For further reading and detailed guidelines, refer to the following resources:

| Resource | Description | Link |

|---|---|---|

| NFPA Standards | Comprehensive guidelines on fire pump sizing and maintenance. | Visit NFPA |

| Fire Pump Manufacturers’ Manuals | Detailed instructions and specifications for various fire pump models. | Visit Manufacturers’ Site |

| Local Fire Safety Codes | Ensure compliance with local regulations and safety standards. | Visit Local Codes |

By following these guidelines, you can effectively size a fire pump for your needs.

Credit: www.ecmweb.com

Frequently Asked Questions

How Do I Choose A Fire Pump Size?

To choose a fire pump size, assess water supply needs, determine required pressure, calculate total head, and consult fire protection standards.

How To Calculate The Fire Pump Capacity?

Calculate fire pump capacity by determining the required flow rate and pressure. Use the formula: Flow Rate = Area x Density. Consult NFPA standards and local regulations for precise requirements. Ensure calculations account for all connected systems and peak demand conditions.

How Do I Choose A Pump Size?

To choose a pump size, consider flow rate, head pressure, fluid type, and system requirements. Consult manufacturer guidelines.

What Is The Rule Of Thumb For Fire Pumps?

The rule of thumb for fire pumps is to ensure they deliver 150% of the rated capacity at 65% of the rated pressure. This ensures reliable performance during emergencies. Proper maintenance and regular testing are also crucial for optimal operation.

Conclusion

Sizing a fire pump correctly ensures optimal safety and efficiency. Remember to consider flow rate, pressure, and system demands. Properly sized fire pumps protect property and lives. Follow these guidelines to achieve the best results. Understanding these basics will help you maintain a reliable fire protection system.

I’m Abdus Sobur, a highly skilled and professional Fire Safety Officer with a passion for safeguarding lives and property. Over the course of my career, I’ve conducted numerous successful fire safety audits, earning a reputation for excellence in ensuring public safety.

In addition to my role as a Fire Safety Officer, I’m also dedicated to raising awareness about the importance of fire safety. Through my blog, I share insights into the functions of different fire safety equipment, aiming to empower individuals with the knowledge they need to protect themselves and their communities.

I’m driven by a deep commitment to promoting fire safety awareness and preventing fire-related incidents.