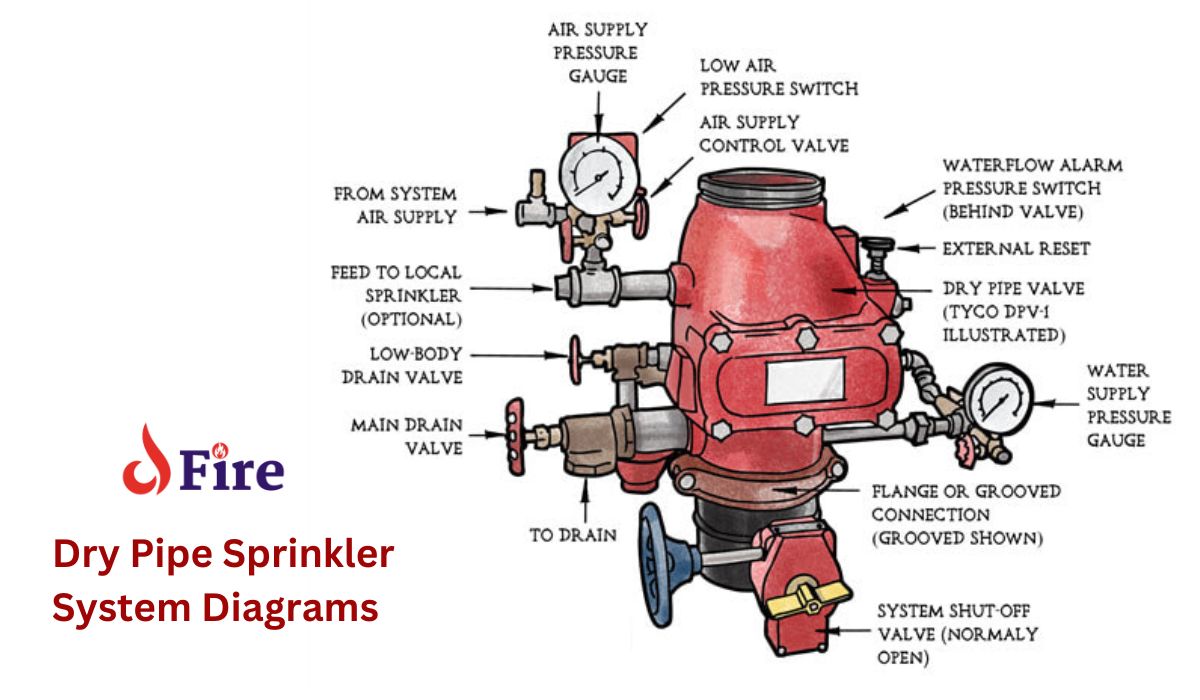

A dry pipe sprinkler system diagram illustrates the components and layout of a dry pipe fire protection system. It shows the arrangement of valves, pipes, and sprinklers.

A dry pipe sprinkler system is a crucial component in fire protection, especially in areas prone to freezing temperatures. Unlike wet pipe systems, dry pipe systems contain pressurized air or nitrogen in the pipes. When a sprinkler head activates, the air pressure drops, opening a valve that allows water to flow through the pipes and extinguish the fire.

This design prevents water from sitting in the pipes, reducing the risk of freezing and subsequent pipe damage. Understanding the diagram helps in proper installation, maintenance, and quick response during emergencies, ensuring safety and compliance with fire safety regulations.

Introduction To Dry Pipe Sprinkler Systems

Dry pipe sprinkler systems are crucial in fire safety, especially in cold environments. They prevent water from freezing in the pipes, ensuring reliable fire protection.

What Is A Dry Pipe System?

A dry pipe system is a type of sprinkler system. It is designed to keep water out of the pipes until a fire is detected. This system uses pressurized air or nitrogen to hold back the water. When a fire occurs, the heat opens the sprinkler heads, releasing the air. This allows water to flow through the pipes and extinguish the fire.

Key Components

A dry pipe system consists of several key components. Each component has a specific role in ensuring the system functions correctly.

| Component | Description |

|---|---|

| Dry Pipe Valve | This valve holds back the water and maintains air pressure in the pipes. |

| Air Compressor | This device keeps the air pressure in the pipes at the required level. |

| Sprinkler Heads | These heads detect heat and open to release the air, allowing water to flow. |

| Pressure Switch | This switch detects changes in pressure and signals the fire alarm system. |

| Alarm | The alarm alerts building occupants to evacuate when the system activates. |

Dry pipe systems are ideal for areas where temperatures drop below freezing. They offer reliable fire protection without the risk of frozen pipes. Ensuring all components are properly maintained is essential for the system to function effectively.

How Dry Pipe Systems Work

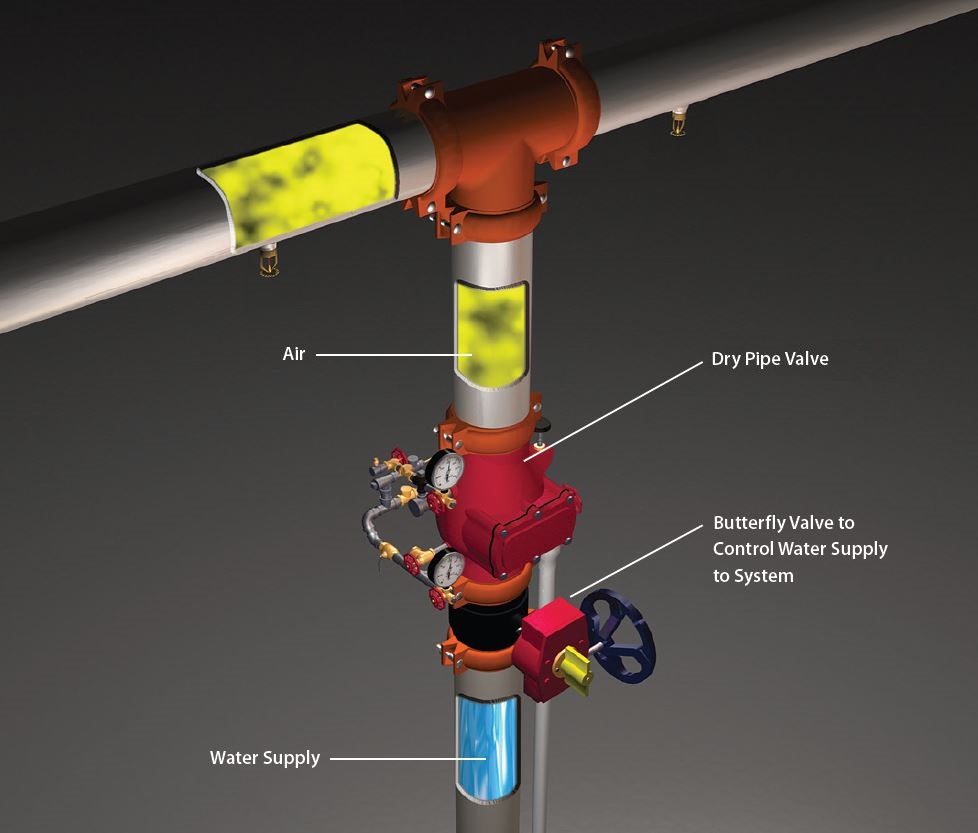

A Dry Pipe Sprinkler System Diagram illustrates the system where pipes contain pressurized air, not water. Upon activation by heat, the air pressure drops, allowing water to flow through the pipes and extinguish the fire.

Dry pipe sprinkler systems are essential for places where water can freeze. These systems are different from wet pipe systems. They are filled with air or nitrogen instead of water. Water only enters the pipes when there is a fire. This prevents freezing and damage in cold areas.

Activation Process

Dry pipe systems have a unique activation process. Here is how it works:

1. Fire Detection: The heat from the fire breaks the glass bulb in the sprinkler head.

2. Air Release: The broken bulb causes air to escape from the pipes.

3. Valve Opens: The pressure drop opens the dry pipe valve.

4. Water Flow: Water rushes into the pipes and out of the sprinkler heads.

The dry pipe valve is crucial in this process. It keeps the water out until the system activates.

Water Delivery Mechanism

The water delivery mechanism is vital in dry pipe systems. Once the valve opens, water travels through the pipes. It reaches the sprinkler heads quickly. Here’s a breakdown:

– Water Source: Water comes from a reliable source, like a tank or mains.

– Pipes: The pipes carry the water to the fire.

– Sprinkler Heads: Water sprays out to extinguish the fire.

Each sprinkler head works independently. Only the heads nearest the fire activate. This reduces water damage in other areas.

Components of Dry Pipe Sprinkler System

| Component | Function |

|---|---|

| Dry Pipe Valve | Controls the flow of water |

| Air Compressor | Keeps air in the pipes |

| Sprinkler Heads | Distributes water over the fire |

Dry pipe systems are effective and reliable. They protect buildings in cold climates. They ensure safety and prevent water damage.

Diagram Breakdown

Understanding the dry pipe sprinkler system diagram is essential for safety. This breakdown will help you know each part and its function. Let’s dive into the details to make things clear.

Major Parts

The dry pipe sprinkler system has several crucial parts. Here are the main components:

- Dry Pipe Valve: This valve keeps water out of the pipes.

- Compressed Air: Air pressure holds the valve closed.

- Sprinkler Heads: These spray water when triggered by heat.

- Alarm Valve: Signals when the system is activated.

- Water Supply: Provides the water needed to douse the fire.

- Control Panel: Monitors and controls the system.

Flow Path

Understanding the flow path in a dry pipe sprinkler system is crucial. Here’s a simple breakdown:

- Activation: Heat from a fire triggers the sprinkler head.

- Air Release: Compressed air escapes the pipe.

- Valve Opens: The dry pipe valve opens due to pressure drop.

- Water Flow: Water flows from the supply through the pipes.

- Sprinkler Discharge: Water sprays from the open sprinkler head.

This flow path ensures that the fire is quickly controlled. Each step is crucial for the system’s efficiency.

Installation Requirements

Installing a dry pipe sprinkler system requires careful planning. It must meet certain criteria to ensure safety and efficiency. Below, we discuss key considerations for the installation process.

Location Considerations

Choosing the right location for a dry pipe sprinkler system is crucial. The system should be installed in areas prone to freezing. This is because the pipes are filled with air, not water.

Consider placing the system in unheated warehouses, parking garages, or attics. Ensure the pipes are accessible for maintenance and inspections.

Avoid locations with high temperatures. Excessive heat can trigger the system unnecessarily.

Regulatory Standards

Compliance with regulatory standards is essential for dry pipe sprinkler systems. The National Fire Protection Association (NFPA) sets the guidelines.

Ensure the system meets NFPA 13 standards. This includes pipe size, valve placement, and system design.

Regular inspections are required to maintain compliance. Keep a record of all inspections and maintenance activities.

Consider the local building codes as well. They may have additional requirements specific to your area.

| Requirement | Description |

|---|---|

| Pipe Size | Must meet NFPA 13 standards |

| Valve Placement | Located in accessible areas |

| System Design | Must prevent water from freezing |

| Inspection Frequency | Regularly, as per NFPA 25 |

Advantages Of Dry Pipe Systems

Dry pipe sprinkler systems offer many benefits. These systems are often used in cold climates. They provide excellent freeze protection and maintenance benefits.

Freeze Protection

Dry pipe systems are ideal for freezing environments. Water is not stored in the pipes. Instead, they hold pressurized air. When a fire starts, the air pressure drops. This opens a valve, allowing water to flow. This design prevents pipes from freezing.

Freeze protection is crucial in warehouses, parking garages, and unheated buildings. These systems ensure fire safety even in harsh winters. Preventing pipe bursts reduces potential damage and repair costs.

Maintenance Benefits

Dry pipe systems require less frequent maintenance. The absence of water in the pipes means less corrosion. This extends the lifespan of the system. Regular checks ensure the air pressure is stable. Simple inspections can be done by trained staff.

For detailed maintenance schedules, refer to the table below:

| Maintenance Task | Frequency |

|---|---|

| Air Pressure Check | Monthly |

| Valve Inspection | Quarterly |

| Full System Test | Annually |

Dry pipe sprinkler systems are reliable and efficient. They provide safety without the constant threat of freezing. Simple maintenance ensures they work when needed.

Common Applications

Dry pipe sprinkler systems are essential in areas where pipes are prone to freezing. These systems ensure fire protection without risking pipe damage from ice. Below are some common applications of dry pipe sprinkler systems.

Cold Storage Facilities

Cold storage facilities often house perishable goods. Maintaining a consistently low temperature is crucial. A dry pipe sprinkler system ensures safety without freezing the pipes. This system keeps water out of the pipes until activation.

These facilities store various items, including:

- Frozen foods

- Pharmaceuticals

- Floral products

Each product type requires a reliable fire protection system. Dry pipe systems provide this reliability in cold environments.

Parking Garages

Parking garages have unique fire protection challenges. These structures are often exposed to the elements. Freezing temperatures can damage traditional sprinkler systems. A dry pipe sprinkler system is an effective solution.

These systems help protect:

- Vehicles

- Structural integrity

- Human lives

Parking garages often have multiple levels. Dry pipe systems can be installed to cover all areas effectively. This ensures comprehensive protection, even in the coldest conditions.

| Application | Benefits |

|---|---|

| Cold Storage Facilities | Prevents pipe freezing, protects perishable goods |

| Parking Garages | Protects vehicles, ensures structural safety |

Maintenance And Inspection

Proper maintenance and inspection of dry pipe sprinkler systems are crucial. Regular checks ensure the system works when needed. Below are key aspects of maintaining and inspecting your dry pipe sprinkler system.

Routine Checks

Routine checks keep your dry pipe sprinkler system in top shape. Follow these simple steps:

- Check valves: Ensure all valves are in the correct position.

- Drain water: Drain any water from the system to prevent freezing.

- Inspect pipes: Look for any signs of corrosion or damage.

- Test alarms: Make sure alarm systems are working properly.

- Review gauges: Check that pressure gauges are within normal ranges.

Troubleshooting Tips

Sometimes, issues may arise with your dry pipe sprinkler system. Use these tips to troubleshoot common problems:

- Low pressure: Check for leaks in the pipes or valves.

- Frozen pipes: Ensure the area is properly heated. Drain water regularly.

- False alarms: Inspect the alarm valve and clean any debris.

- Corrosion: Look for rust and replace damaged pipes.

- Valve issues: Make sure valves are not stuck or blocked.

Maintaining and inspecting your dry pipe sprinkler system is vital. Routine checks and troubleshooting can prevent major problems. Follow these steps to keep your system reliable and effective.

Credit: blog.qrfs.com

Comparing Wet And Dry Systems

Understanding the differences between wet and dry pipe sprinkler systems is crucial. Each system has unique features and benefits. Choosing the right one depends on the specific needs of your building.

Performance Differences

Wet pipe systems are the most common type of sprinkler systems. They have water in the pipes at all times. This allows for immediate activation of water flow. They are reliable and easy to maintain.

Dry pipe systems are different. They have air or nitrogen in the pipes instead of water. Water only enters the pipes when the system activates. This makes them ideal for freezing environments. They prevent the risk of water freezing in the pipes.

| Feature | Wet Pipe System | Dry Pipe System |

|---|---|---|

| Activation Time | Immediate | Delayed |

| Environment Suitability | Non-freezing | Freezing |

| Maintenance | Easy | Complex |

Cost Analysis

The initial cost of installing wet pipe systems is usually lower. They require fewer components and are simpler to install. This makes them a cost-effective option for many buildings.

Dry pipe systems tend to be more expensive. They need additional components like air compressors. This increases both the installation and maintenance costs.

- Wet Pipe Systems:

- Lower initial cost

- Less maintenance

- Dry Pipe Systems:

- Higher initial cost

- More maintenance

Future Trends

The future of dry pipe sprinkler systems is exciting. As technology evolves, new trends emerge. These trends aim to enhance efficiency, sustainability, and safety. Below, we explore key future trends in dry pipe sprinkler systems.

Technological Advancements

Technological advancements are transforming dry pipe sprinkler systems. Innovations like smart sensors and IoT integration are leading the way. These technologies allow real-time monitoring and automated responses.

Smart sensors can detect fire faster. They also reduce false alarms. IoT integration enables seamless communication between devices. This ensures a quick and coordinated response during emergencies.

Another exciting advancement is predictive maintenance. This technology can foresee potential issues before they occur. It helps in maintaining the system’s reliability and efficiency.

Sustainability Practices

Sustainability is becoming a key focus in fire safety. Eco-friendly materials are now being used in sprinkler systems. These materials are recyclable and have a lower environmental impact.

Water conservation is another critical aspect. Dry pipe systems are designed to use water efficiently. This helps in reducing water wastage during fire incidents.

Energy-efficient components are also being integrated into these systems. These components reduce energy consumption and enhance the system’s overall sustainability.

| Technological Advancements | Sustainability Practices |

|---|---|

| Smart Sensors | Eco-friendly Materials |

| IoT Integration | Water Conservation |

| Predictive Maintenance | Energy-efficient Components |

These trends are shaping the future of dry pipe sprinkler systems. They promise a safer, more efficient, and sustainable approach to fire safety.

Frequently Asked Questions

What Is A Dry Pipe Sprinkler System?

A dry pipe sprinkler system holds pressurized air or nitrogen in the pipes. Water fills the pipes when a fire activates the system. Ideal for cold environments, it prevents pipe freezing. This system is reliable and effective for fire protection.

What Are The Disadvantages Of A Dry Pipe Sprinkler System?

Dry pipe sprinkler systems have delayed response times. They require more maintenance and are prone to corrosion. Installation costs are higher. Water can freeze in pipes, causing damage.

What Is The Life Expectancy Of A Dry Pipe Sprinkler System?

A dry pipe sprinkler system typically lasts 10 to 15 years. Regular inspections and maintenance can extend its lifespan.

What Is The Slope For A Dry Sprinkler System?

The slope for a dry sprinkler system should be a minimum of 1/2 inch per 10 feet. This ensures proper drainage.

Conclusion

A dry pipe sprinkler system diagram is essential for safety planning. It helps in understanding system components and operation. Proper knowledge ensures efficient installation and maintenance. Always refer to the diagram for troubleshooting. This can significantly enhance fire protection measures in your facility.

Stay safe and prepared with accurate system insights.

I’m Abdus Sobur, a highly skilled and professional Fire Safety Officer with a passion for safeguarding lives and property. Over the course of my career, I’ve conducted numerous successful fire safety audits, earning a reputation for excellence in ensuring public safety.

In addition to my role as a Fire Safety Officer, I’m also dedicated to raising awareness about the importance of fire safety. Through my blog, I share insights into the functions of different fire safety equipment, aiming to empower individuals with the knowledge they need to protect themselves and their communities.

I’m driven by a deep commitment to promoting fire safety awareness and preventing fire-related incidents.