Fire pump rooms must comply with NFPA 20 standards. These include adequate space, ventilation, and accessibility for maintenance.

Fire pump rooms are critical for ensuring effective fire protection in buildings. According to NFPA 20, these rooms must meet specific requirements to ensure safety and functionality. The room should be spacious enough for equipment maintenance and inspections. Proper ventilation is crucial to prevent overheating and ensure optimal performance.

Accessibility for authorized personnel must be straightforward, without any obstructions. Following these guidelines helps in maintaining a reliable fire suppression system, thereby safeguarding lives and property. Compliance with NFPA 20 not only ensures safety but also helps in avoiding potential legal and insurance issues.

Introduction To NFPA Standards

Fire pump rooms are crucial for fire safety. The National Fire Protection Association (NFPA) sets important standards. These standards ensure that fire pump rooms are safe and effective.

Importance Of Fire Safety

Fire safety is vital for protecting lives and property. Proper fire pump room setups help control fires. They provide water pressure to sprinkler systems. This can mean the difference between life and death.

Having a well-maintained fire pump room reduces risks. It ensures swift response during emergencies. Following NFPA standards helps achieve this goal.

Role Of Nfpa

The NFPA creates guidelines for fire safety. These guidelines cover many aspects, including fire pump rooms. They ensure fire systems are reliable and effective.

NFPA standards include:

- Design specifications

- Installation guidelines

- Maintenance requirements

Adhering to NFPA standards helps ensure safety. It also helps meet legal requirements.

| NFPA Standard | Description |

|---|---|

| NFPA 20 | Standard for the Installation of Stationary Pumps for Fire Protection |

| NFPA 25 | Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems |

By following these standards, buildings stay safer. Fire pump rooms must meet these guidelines for optimal performance.

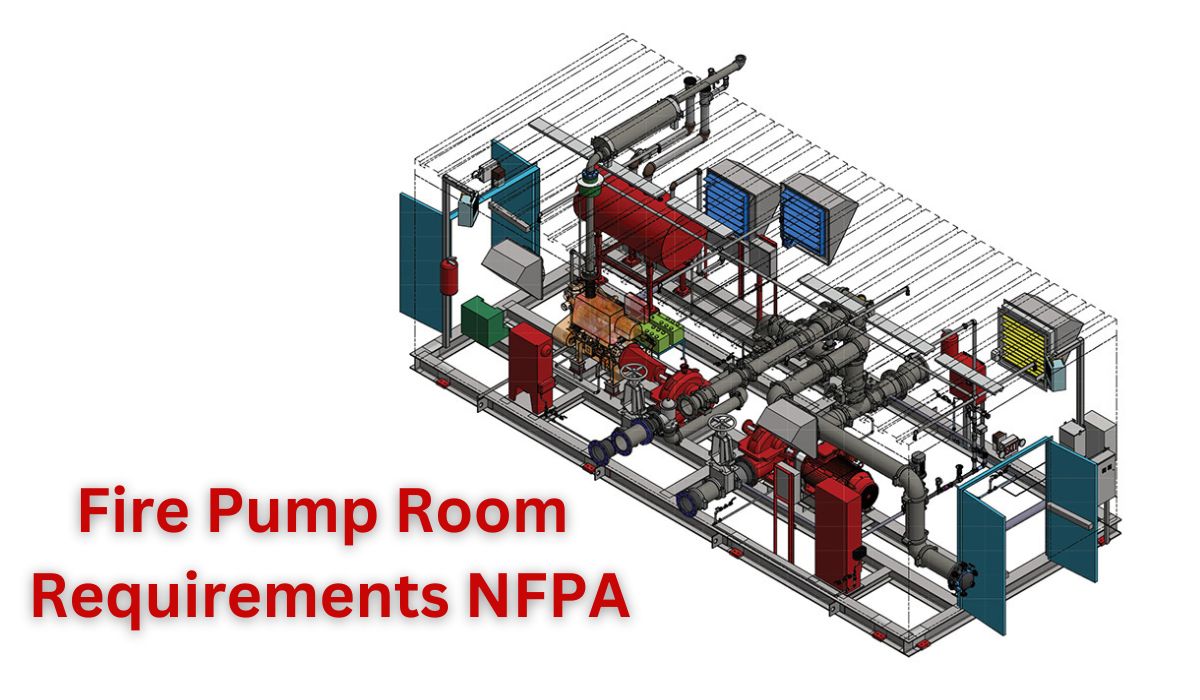

Fire Pump Room Basics

Understanding the basics of a fire pump room is crucial for safety. A fire pump room houses essential equipment for firefighting. It helps maintain water pressure in fire protection systems.

Definition And Purpose

A fire pump room is a dedicated area for fire pumps. These pumps boost water pressure in sprinkler systems. The main purpose is to ensure water flows effectively during a fire. This helps in controlling and extinguishing fires quickly.

Key Components

A fire pump room contains several key components. Each part plays a vital role in the system’s performance:

- Fire Pump: The main device that increases water pressure.

- Jockey Pump: Maintains system pressure during normal conditions.

- Controller: Starts and stops the fire pump.

- Relief Valve: Prevents over-pressurization.

- Test Header: Used to test the pump’s performance.

Other important elements include:

- Power Supply

- Water Source

- Piping

- Valves

| Component | Function |

|---|---|

| Fire Pump | Boosts water pressure |

| Jockey Pump | Maintains system pressure |

| Controller | Manages pump operation |

| Relief Valve | Prevents excess pressure |

| Test Header | Allows performance testing |

Each component must meet NFPA standards. This ensures reliability and efficiency. Regular maintenance is also necessary.

Location And Accessibility

Choosing the right location for a fire pump room is critical. It ensures quick access and efficient operation. This section will cover optimal placement and access requirements according to NFPA standards.

Optimal Placement

Placing the fire pump room in a strategic location is vital. Ideally, it should be near the building’s main water supply. This reduces the distance and potential for water pressure loss.

The room should be away from areas prone to flooding. This protects the equipment from water damage. Additionally, it should be in a low-traffic area. This minimizes the risk of accidental damage or tampering.

Access Requirements

Access to the fire pump room must be clear and unobstructed. Emergency personnel need quick entry during a crisis. The entrance door should be wide enough for equipment transport.

The door must also be fire-rated. This ensures it can withstand fire exposure. Clearly marked signage should be present. This helps in identifying the room quickly.

Regular maintenance requires easy access too. Hence, keep the area around the fire pump room free of obstacles. This allows for routine checks and repairs without hindrance.

Ventilation And Temperature Control

Proper ventilation and temperature control in a fire pump room ensures safety and efficiency.

The NFPA outlines specific requirements to maintain these conditions. This section covers the essentials.

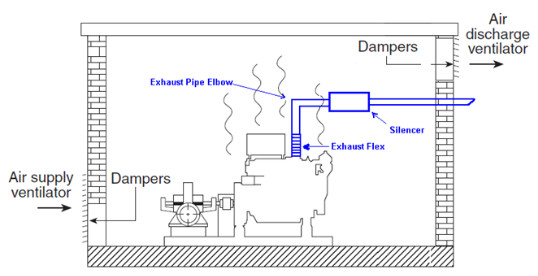

Ventilation Needs

Fire pump rooms must have adequate ventilation. This prevents the buildup of harmful fumes and maintains air quality.

Ventilation can be achieved through natural means or mechanical systems. The NFPA requires that air exchange rates meet specific standards.

Here are some key points for ventilation needs:

- Air Exchange Rate: Ensure proper air changes per hour.

- Exhaust Fans: Install fans to remove fumes.

- Fresh Air Inlets: Provide inlets for fresh air circulation.

Temperature Regulations

Maintaining the right temperature is crucial for fire pump efficiency. The NFPA specifies temperature ranges for fire pump rooms.

The minimum temperature should not fall below 40°F (4°C). The maximum temperature should not exceed 120°F (49°C).

Use heating and cooling systems to control the temperature. Monitor temperatures regularly to ensure compliance.

Here is a table summarizing the temperature requirements:

| Temperature Range | Requirement |

|---|---|

| Minimum Temperature | 40°F (4°C) |

| Maximum Temperature | 120°F (49°C) |

Electrical And Power Supply

The electrical and power supply of a fire pump room is crucial. It ensures the pump operates during emergencies. The NFPA sets strict guidelines for these systems.

Primary Power Source

The primary power source must be reliable. It should provide continuous power to the fire pump. This source is usually the main electrical utility.

| Requirement | Details |

|---|---|

| Voltage | Must match pump specifications |

| Connection | Direct to the utility grid |

| Reliability | Must ensure uninterrupted supply |

Backup Power Systems

A backup power system is essential. It acts if the primary source fails. Diesel generators are the most common backup.

- Automatic Transfer Switch (ATS): Switches to backup power instantly.

- Fuel Supply: Must have enough fuel for at least 8 hours.

- Maintenance: Regular checks ensure readiness.

Other backup options include battery systems. They are less common but effective. They should meet the NFPA standards too.

Room Construction And Materials

Understanding the requirements for a fire pump room is crucial for safety. This section covers the essential aspects of Room Construction and Materials. Proper construction and materials ensure the room’s durability and safety.

Approved Materials

The fire pump room must use approved materials. These materials should be non-combustible and meet NFPA standards. Using the correct materials helps prevent fire spread.

- Concrete – Commonly used for walls and floors.

- Steel – Often used for structural support.

- Fire-rated Gypsum Board – Used for additional fire protection.

Structural Integrity

The fire pump room’s structural integrity is essential. The room must withstand fire and other hazards. Key factors include:

- Wall Thickness: Walls should be thick enough to resist fire.

- Reinforcement: Use steel or other materials to reinforce walls.

- Sealing: Proper sealing prevents smoke and fire spread.

Below is a table summarizing the construction materials and their applications:

| Material | Application |

|---|---|

| Concrete | Walls and Floors |

| Steel | Structural Support |

| Fire-rated Gypsum Board | Additional Fire Protection |

Maintenance And Inspections

Keeping fire pump rooms in top condition is vital. Routine maintenance and regular inspections ensure safety and performance. Adhering to NFPA standards is essential. This section covers key practices for maintaining and inspecting fire pump rooms.

Routine Maintenance

Routine maintenance is crucial to keeping fire pump rooms operational. Regular tasks include:

- Checking oil levels in pumps

- Testing the battery voltage

- Inspecting and cleaning filters

- Lubricating moving parts

- Ensuring all connections are tight

Perform these tasks monthly for optimal performance.

Regular Inspections

Regular inspections help identify potential issues early. Key inspection points include:

- Checking for leaks or drips

- Ensuring the area is free from obstructions

- Verifying the condition of electrical connections

- Inspecting for signs of wear and tear

- Testing alarm systems for functionality

Conduct these inspections quarterly to ensure compliance with NFPA standards.

Use a checklist for thorough inspections:

| Inspection Task | Frequency |

|---|---|

| Check for leaks | Quarterly |

| Clear obstructions | Quarterly |

| Verify electrical connections | Quarterly |

| Inspect wear and tear | Quarterly |

| Test alarm systems | Quarterly |

Following these steps ensures a reliable fire pump room. This helps in emergencies and enhances safety.

Compliance And Certification

Ensuring fire pump rooms meet NFPA standards is crucial for safety. Compliance and certification guarantee that fire pump systems function properly during emergencies. This section explains the key aspects of NFPA compliance and the certification process.

Nfpa Compliance

NFPA stands for the National Fire Protection Association. They set safety standards for fire pump rooms. These standards include guidelines on installation, maintenance, and operation.

Fire pump rooms must have adequate ventilation. This prevents overheating of the equipment. The room should also have proper lighting for maintenance tasks.

An important requirement is the presence of a dedicated power supply. This ensures the pump operates during power outages. The room must also be free from combustible materials. This reduces the risk of fire spread.

Certification Process

The certification process involves several steps. First, an inspection by a certified professional is required. They check if the fire pump room meets all NFPA standards.

Next, a compliance report is generated. This report highlights any deficiencies found during the inspection. The facility must address these issues to achieve certification.

Once all issues are resolved, a final inspection is scheduled. If the fire pump room meets all requirements, a certification document is issued.

Regular inspections are necessary to maintain certification. This ensures ongoing compliance with NFPA standards.

The table below summarizes the key steps in the certification process:

| Step | Description |

|---|---|

| Inspection | Certified professionals check NFPA compliance |

| Compliance Report | Report generated, highlighting deficiencies |

| Issue Resolution | The facility addresses highlighted issues |

| Final Inspection | Ensures all requirements are met |

| Certification | Document issued if compliant |

Ensuring NFPA compliance and obtaining certification enhances fire safety. It ensures the fire pump room operates effectively during emergencies.

Common Challenges

Fire pump rooms are essential for safety in buildings. They ensure reliable fire protection. However, they come with several challenges. Understanding these challenges helps in maintaining them effectively.

Typical Issues

Several common issues arise in fire pump rooms:

- Space Constraints: Limited space can hinder equipment layout.

- Ventilation Problems: Poor ventilation leads to overheating.

- Electrical Failures: Faulty wiring affects pump operation.

- Maintenance Access: Difficult access complicates maintenance tasks.

- Water Supply: Inadequate water supply impacts pump efficiency.

Solutions And Best Practices

Implementing solutions helps mitigate these issues:

| Issue | Solution | Best Practice |

|---|---|---|

| Space Constraints | Optimize layout with compact equipment. | Plan space during design phase. |

| Ventilation Problems | Install efficient ventilation systems. | Regularly check and clean vents. |

| Electrical Failures | Ensure proper electrical installations. | Conduct routine electrical inspections. |

| Maintenance Access | Design for easy access to equipment. | Schedule regular maintenance checks. |

| Water Supply | Ensure a reliable water source. | Monitor water levels frequently. |

Credit: www.csemag.com

Future Trends

The future of fire pump room requirements is evolving rapidly. The NFPA standards are adapting to new technologies and practices. These changes aim to enhance safety and efficiency.

Technological Advancements

Technological advancements are transforming fire pump room designs. Smart sensors and automated systems play a crucial role. They provide real-time data and alerts.

IoT integration is another exciting trend. It allows for better monitoring and control. Remote access enables quick responses to emergencies.

3D modeling and simulation tools help in designing efficient spaces. They ensure the optimal placement of equipment. This reduces human errors and boosts reliability.

Evolving Standards

NFPA standards are constantly evolving. They incorporate new research and best practices. This ensures fire pump rooms are safe and effective.

Sustainability is a key focus. New standards emphasize energy-efficient and eco-friendly solutions. This reduces the environmental impact.

Regulatory updates are frequent. Staying updated with these is crucial. Compliance with the latest standards ensures safety and legality.

Frequently Asked Questions

What Is The Nfpa Standard For A Fire Pump Room?

The NFPA standard for a fire pump room is NFPA 20. It outlines requirements for installation, maintenance, and operation. Ensure compliance for safety and efficiency.

Do Fire Pumps Need To Be In A Room?

Yes, fire pumps need to be in a dedicated room. This ensures they operate safely and efficiently.

How Much Ventilation Is Required For Fire Pump Room?

Fire pump rooms need ventilation to remove heat and fumes. A minimum of 5 air changes per hour is recommended. Proper airflow ensures equipment efficiency and safety.

How Big Should A Fire Pump Room Be?

A fire pump room should be at least 150 square feet. Ensure enough space for maintenance and clearances.

Conclusion

Meeting NFPA fire pump room requirements ensures safety and compliance. Proper design, maintenance, and regular inspections are essential. Adhering to these standards can prevent costly damages and save lives. Stay informed and proactive in your fire safety measures to protect both property and personnel effectively.

I’m Abdus Sobur, a highly skilled and professional Fire Safety Officer with a passion for safeguarding lives and property. Over the course of my career, I’ve conducted numerous successful fire safety audits, earning a reputation for excellence in ensuring public safety.

In addition to my role as a Fire Safety Officer, I’m also dedicated to raising awareness about the importance of fire safety. Through my blog, I share insights into the functions of different fire safety equipment, aiming to empower individuals with the knowledge they need to protect themselves and their communities.

I’m driven by a deep commitment to promoting fire safety awareness and preventing fire-related incidents.